Pod kopi sekali saji, seperti K-cups, telah mengubah industri kopi, menawarkan kenyamanan dan kualitas kepada konsumen dalam setiap minumannya. Jika Anda adalah pemilik bisnis kopi—baik roastery kecil, kafe, atau produsen skala besar—berinvestasilah pada Mesin pengisi K-cup bisa menjadi langkah besar Anda berikutnya. Mesin ini menyederhanakan proses pengisian kopi ke dalam K-cup dan menyegelnya, memastikan konsistensi dan efisiensi. Namun dengan banyaknya pilihan yang tersedia, bagaimana cara memilih yang tepat?

Dalam panduan ini, saya akan memanfaatkan pengalaman saya selama bertahun-tahun di industri permesinan untuk membantu Anda menjelajahi dunia mesin pengisian K-cup. Kami akan membahas semuanya mulai dari fungsi mesin ini hingga faktor utama yang harus Anda pertimbangkan sebelum membeli. Harapkan jawaban atas pertanyaan umum seperti “Berapa harga mesin pengisi K-cup?” dan “Apa perbedaan antara model manual dan otomatis?”—semuanya menggabungkan wawasan dari penelusuran pengguna sebenarnya. Mari selami!

Apa Itu Mesin Pengisian K-Cup dan Mengapa Anda Membutuhkannya?

Mesin pengisian K-cup adalah peralatan khusus yang dirancang untuk mengotomatiskan produksi biji kopi satu porsi. Ini mengisi K-cup yang sudah dibentuk sebelumnya dengan kopi (atau minuman lain), menutupnya dengan penutup, dan menyiapkannya untuk dikemas.

Mesin-mesin ini merupakan terobosan baru bagi bisnis yang ingin memproduksi K-cup bermerek mereka sendiri, dengan menawarkan manfaat seperti:

- Kontrol Atas Kualitas: Anda menentukan campuran kopi, gilingan, dan ukuran porsi.

- Penghematan Biaya: Memproduksi sendiri dapat mengurangi ketergantungan pada pemasok pihak ketiga.

- Perluasan Pasar: Tawarkan rasa unik atau pod bermerek agar menonjol.

Baik Anda adalah perusahaan rintisan yang sedang menguji coba atau perusahaan mapan yang sedang berkembang, mesin pengisian K-cup dapat menghemat waktu, memastikan konsistensi, dan memenuhi permintaan yang terus meningkat. Namun dengan berbagai jenis dan fitur yang tersedia, penting untuk memahami pilihan Anda.

Jenis Mesin Pengisian K-Cup : Manual, Semi Otomatis, dan Otomatis

Salah satu pertanyaan pertama yang diajukan pembeli adalah, “Apa perbedaan antara mesin pengisian K-cup manual dan otomatis?” Berikut rincian tiga jenis utama:

Mesin Pengisian K-Cup Manual

- Ringkasan: Mesin ini mengharuskan operator untuk menangani sebagian besar langkah—menempatkan cangkir, mengisi kopi, dan menutup tutup. Mereka ideal untuk produksi skala kecil atau bisnis yang baru dimulai.

- Pro: Terjangkau (mulai dari beberapa ratus dolar), ringkas, dan mudah digunakan untuk volume rendah.

- Kontra: Kapasitas padat karya dan terbatas (misalnya, AF-BZD95 menyegel hingga 600 cangkir per jam dengan pengoperasian terampil).

- Terbaik untuk: Startup atau kedai kopi kecil yang memproduksi 100–500 K-cups setiap hari.

Mesin Pengisian K-Cup Semi-Otomatis

- Ringkasan: Ini mencapai keseimbangan, mengotomatiskan bagian-bagian proses (seperti pengisian atau penyegelan) sambil tetap memerlukan input manual.

- Pro: Lebih cepat dibandingkan mesin manual, harga terjangkau, dan cocok untuk bisnis yang sedang berkembang.

- Kontra: Masih memerlukan keterlibatan operator, sehingga membatasi skalabilitas.

- Terbaik untuk: Pabrik pemanggang berukuran sedang yang memproduksi 500–2000 K-cup setiap hari.

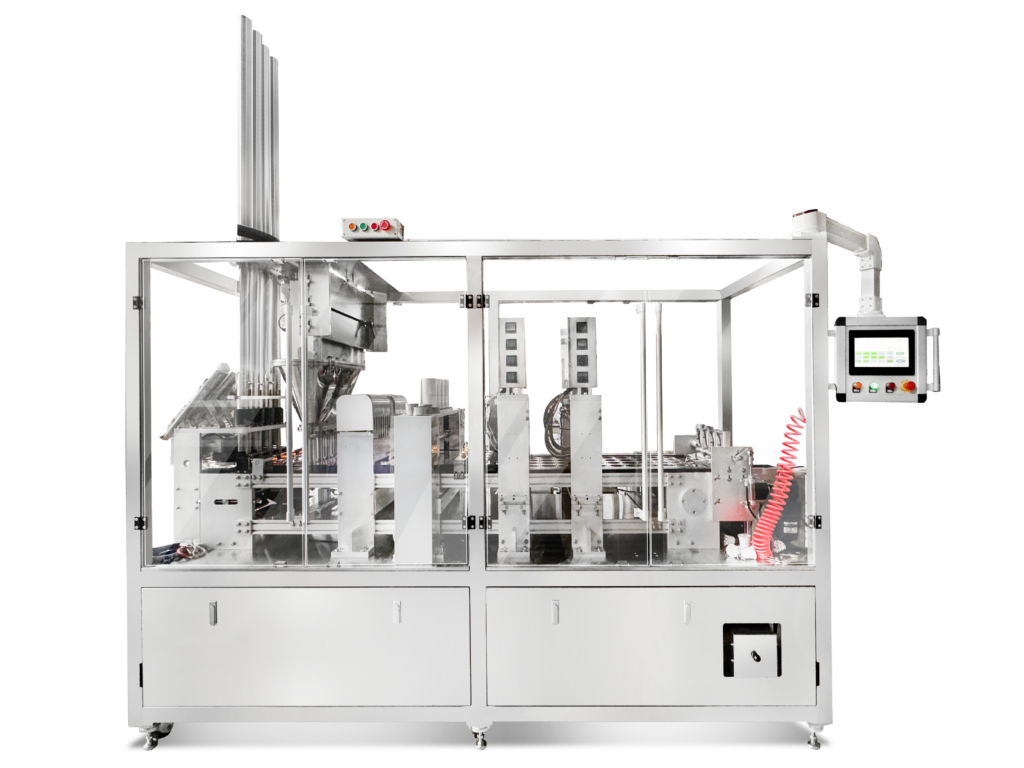

Mesin Pengisian K-Cup Sepenuhnya Otomatis

- Ringkasan: Ini menangani semuanya—pengumpanan cangkir, pengisian, penyegelan, dan pengeluaran—dengan sedikit campur tangan manusia. Pikirkan solusi teknologi tinggi seperti AF-RN1S dari AFPAK, yang menghasilkan hingga 3000 K-cup per jam.

- Pro: High efficiency, consistent output, and advanced features like nitrogen flushing.

- Kontra: Higher cost (often $20,000+) and larger footprint.

- Terbaik untuk: Large producers or businesses planning rapid growth.

Key Takeaway: Match the machine type to your production needs and budget. Starting small? Go manual. Scaling up? Consider semi-automatic or automatic.

Fitur Utama yang Harus Diperhatikan dalam Mesin Pengisian K-Cup

When researching “What should I look for in a K-cup filling machine?” several features stand out as must-haves. Here’s what to prioritize:

- Kapasitas produksi: How many K-cups do you need daily? Manual machines handle small runs, while automatic ones tackle thousands per hour (e.g., AFPAK YM40 offers 1500-2400 cups/hour).

- Mengisi Akurasi: Precision matters for taste consistency. Look for machines with servo-motor augers boasting accuracies of ±0.2 grams.

- Teknologi Penyegelan: A strong, airtight seal preserves freshness. Heat and pressure sealing with adjustable settings is ideal.

- Ease of Use and Cleaning: Intuitive controls (like touch screens) and easy-to-clean designs reduce downtime—a must for busy operations.

- Pembilasan Nitrogen: This feature reduces oxygen in the cup, extending shelf life and maintaining flavor. It’s a premium add-on worth considering.

- Kustomisasi: Need branded lids or different cup sizes? Machines like those from AFPAK offer tailored options.

Pro Tip: Test these features against your goals. If quality and shelf life are priorities, filling accuracy,nitrogen flushing and sealing tech should top your list.

Fungsi Khusus dan Fitur Opsional Mesin Pengisian K-Cup Sepenuhnya Otomatis

Fully automatic K-cup filling machines are engineered to streamline the production process with minimal human intervention, delivering high efficiency, consistency, and quality. These machines come equipped with essential standard functions for large-scale production, along with optional features that allow businesses to customize them according to specific needs. Below, we detail both the core functions and the optional enhancements available.

Fungsi Standar Mesin Pengisian K-Cup Sepenuhnya Otomatis

These machines integrate a set of key functions to fully automate K-cup production. Here’s what they typically include:

- Automatic Cup Feeding: Empty K-cups are automatically loaded into the production line from a hopper or feeding system, ensuring a steady supply without manual effort.

- Precise Filling: Servo-driven augers or advanced metering systems fill each K-cup with coffee (or other products like tea or cocoa) to an accuracy of ±0.2 grams, guaranteeing uniformity.

- Tamping and Cleaning: Post-filling, the machine tamps the contents for consistent density and cleans the cup’s rim to remove residue, preparing it for sealing.

- Lid Placement and Sealing: Pre-cut lids (or lids cut from a roll) are automatically placed and sealed onto the K-cups using heat and pressure, ensuring an airtight closure to preserve freshness.

- Pembilasan Nitrogen: A standard feature in many models, this reduces oxygen levels inside the K-cup to below 2%, extending shelf life and maintaining flavor integrity.

- Quality Control Sensors: Built-in sensors monitor for defects like missing cups, misaligned lids, or filling errors, automatically rejecting faulty units to uphold quality standards.

- Automatic Discharge: Finished K-cups are ejected from the machine automatically, ready for packaging or further processing.

- Touchscreen Interface: An intuitive touchscreen allows operators to monitor performance, adjust settings (e.g., fill weight or sealing temperature), and address issues in real-time.

These core functions make fully automatic K-cup filling machines a reliable solution for businesses aiming to produce K-cups efficiently at scale.

Fitur Opsional untuk Peningkatan Kustomisasi

Beyond standard capabilities, manufacturers offer optional features to meet diverse production demands. Here are some common enhancements:

- Filter Insertion: Automatically inserts filters before filling, ideal for loose-leaf tea or specialty coffee blends requiring filtration.

- Multi-Format Compatibility: Enables the machine to produce various single-serve pod types (e.g., K-cups and Nespresso-compatible capsules) with quick-change parts, reducing downtime.

- Flavor Addition: Adds a system to inject precise amounts of liquid flavoring during filling, perfect for flavored coffee or unique product lines.

- In-Line Weighing System: Enhances quality control with real-time weight checks for each K-cup, complementing the standard filling precision.

- Roll Stock Cutting and Sealing: Uses a roll stock system to cut and seal lids on-site, cutting material costs and waste compared to pre-cut lids, especially in high-volume runs.

- Nitrogen Generator Integration: Pairs with nitrogen flushing by integrating an on-board nitrogen generator, offering a cost-effective, efficient supply.

- Remote Monitoring and Control: Provides remote access to production data and machine performance via mobile devices or computers, improving oversight.

- Automatic Cartoning and Packaging: Adds modules to pack finished K-cups into boxes or other formats automatically, minimizing manual labor.

- UV Sterilization: Incorporates UV systems to sterilize cups before filling, meeting high hygiene standards for sensitive products.

These optional features allow businesses to adapt the machine to specific production goals, enhancing versatility and efficiency.

Mengapa Fungsi Ini Penting

The combination of standard and optional functions offers significant benefits:

- Efisiensi: Automation features like cup feeding and automatic discharge boost production speed and scalability.

- Kualitas: Sensors and weighing systems ensure consistent, defect-free output.

- Kustomisasi: Options like flavor addition and multi-format compatibility enable diverse product offerings.

- Penghematan Biaya: Features like roll stock sealing and nitrogen generators reduce long-term operational costs.

Berapa Biaya Mesin Pengisian K-Cup?

A top Google query is, “How much does a K-cup filling machine cost?” Prices vary widely:

- Manual Machines: Start at $800–$1000. AFPAK’s starter kit, including 1000 cups, is under $2000.

- Semi-Automatic Machines: Range from $1000–$3,000, depending on features.

- Fully Automatic Machines: Begin at $15,000 and can exceed $50,000 for high-end models like AFPAK’s.

Biaya Tersembunyi yang Perlu Dipertimbangkan

- Pemeliharaan: Regular servicing and parts (e.g., seals or augers) add up.

- Training: Operators may need training, especially for automatic systems.

- Energy: Larger machines consume more power, impacting utility bills.

- Financing: Many suppliers (e.g., CoffeeTec) offer payment plans to ease the upfront hit.

Budgeting Advice: Calculate the total cost of ownership—purchase price plus ongoing expenses—to avoid surprises.

Dukungan Purna Jual dan Garansi: Mengapa Itu Penting

In the machinery world, support can make or break your experience. A machine breakdown with no help in sight is a nightmare. Here’s what to check:

- Dukungan teknis: Look for 24/7 assistance, installation help, and training. AFPAK excels here with round-the-clock online support.

- Jaminan: Standard is one year on parts, but some (like CoffeeTec) offer extensions. Clarify coverage details—does it include labor?

- Parts Availability: Quick access to spares minimizes downtime. Ask about shipping times.

- Local Service: If possible, choose a supplier with nearby technicians.

Industry Insight: I’ve seen businesses thrive with reliable support and struggle without it. Prioritize manufacturers with a solid reputation.

Memastikan Kepatuhan terhadap Standar Keselamatan

Since K-cups are food products, safety is non-negotiable. Your machine should meet standards like:

- CE Certification: Common in Europe, ensures safety and quality.

- ISO Standards: Signals consistent manufacturing practices.

- FDA Compliance: Critical for U.S. markets, ensuring food-safe materials.

Machines from reputable brands like AFPAK often carry CE and ISO certifications. Stainless steel construction and hygienic designs further boost compliance.

Quick Check: Ask suppliers for certification proof—it’s your assurance of quality.

Kustomisasi dan Kompatibilitas: Memenuhi Kebutuhan Unik Anda

“Are there K-cup filling machines that can handle different cup sizes?” Yes, and here’s how:

- Cup Compatibility: Confirm the machine supports your K-cups—standard, K-shots, or others. Some handle multiple formats.

- Branding Options: Want your logo on lids? Companies like AFPAK offer customization.

- Integration: Need it to work with existing gear? Look for adaptable designs (AFPAK machines integrate seamlessly).

Expert Note: Customization can set your product apart—don’t overlook it if branding matters.

Cara Memilih Mesin Pengisian K-Cup yang Tepat untuk Bisnis Anda

Here’s a step-by-step guide to answer, “How do I pick the best K-cup filling machine?”

- Define Production Goals: How many K-cups daily? Small runs (100–500) suit manual machines; high volumes (2000+) need automatic.

- Set a Budget: Include purchase and operating costs. Financing can help with pricier models.

- Measure Space: Manual machines fit tight spots; automatic ones need room (check dimensions online).

- Plan for Growth: A scalable machine prevents future upgrades. Semi-automatic is a good middle ground.

- Research Support: Read reviews or ask for references. Good service is worth the price.

- Verify Compliance: Ensure certifications match your market’s regulations.

- Test It Out: If possible, see it in action via demo or trial.

Real-World Example: A client of mine started with a manual machine, scaled to semi-automatic within a year, and now runs an automatic line—all because they planned ahead.

Pemikiran Terakhir: Melakukan Investasi yang Tepat

Buying a Mesin pengisi K-cup is a big decision, but it’s one that can elevate your coffee business. Whether you’re dipping your toes with a manual model or diving into high-volume production with an automatic system, the key is matching the machine to your needs, budget, and growth plans.

From my years in the machinery industry, I’ve learned that the best choices balance cost, quality, and support. Research thoroughly, ask suppliers tough questions, and don’t skimp on safety or service. With the right K-cup filling machine, you’ll produce top-notch pods that keep customers brewing—and coming back for more.

Ready to start shopping? Use this guide as your roadmap, and you’ll find the perfect machine to fuel your coffee dreams.