How Can You Perfectly Capture Brazil's Samba-Infused Coffee in a Capsule?

Losing the soul of specialty coffee during packaging is a real fear. Standard methods can strip away delicate flavors, but the right technology preserves every vibrant note from bean to cup.

To capture Brazil's unique coffee flavor in a capsule, you need precise auger filling technology. This method protects delicate aromas and ensures accurate dosing, preserving the coffee's vibrant character, much like a Samba dancer's every step is full of passion and precision.

When I think of Brazil, I think of two things: the energetic rhythm of Samba and the rich, complex taste of its coffee. Both are full of life and passion. Bringing them together in a coffee capsule is a fantastic idea, but it's also a big challenge. You want to deliver an experience, not just a drink. The process has to be perfect to protect that special flavor. Let's explore how we can make sure the spirit of Brazil makes it all the way into the final cup.

How can you capture the vibrant essence of Brazilian coffee in a capsule?

You have amazing Brazilian coffee, but you worry that the capsule will lose its soul. The wrong process can turn a lively flavor into a flat, boring brew.

To capture the essence, use a nitrogen flushing system combined with gentle auger filling. Nitrogen displaces oxygen, preventing oxidation. The auger filler carefully doses the coffee, preserving its complex flavor profile from the first grind to the final brew, locking in that Brazilian spirit.

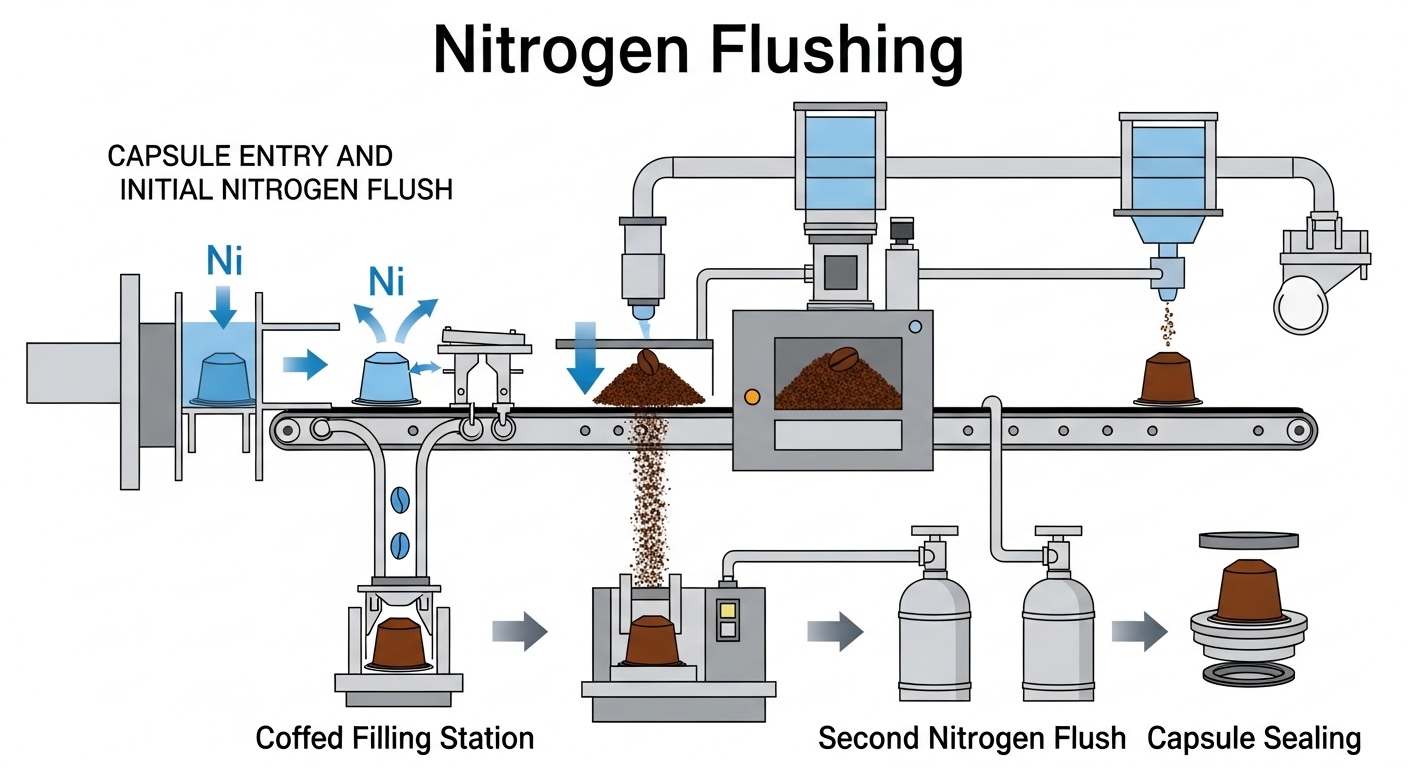

The biggest enemy of fresh coffee is oxygen. It starts to degrade the aromatic compounds almost immediately after grinding. Think of it like a Samba rhythm fading out—the energy is lost. To keep the party going inside the capsule, we have to get the oxygen out. This is where nitrogen flushing comes in. Before we seal the capsule, we push a puff of nitrogen gas into it. Nitrogen is inert, meaning it doesn't react with the coffee. It pushes the oxygen out, creating a protective atmosphere inside. This simple step can extend the shelf life and preserve the fresh-ground taste for months. I always tell my clients that this is not an optional feature; it's essential for any premium coffee product. It’s the difference between a coffee that tastes alive and one that tastes old.

Key Preservation Techniques

| Technique | Primary Function | Impact on Flavor |

|---|---|---|

| Stikstofspoelen | Removes oxygen from the capsule | Prevents oxidation, preserves original aroma and taste |

| Gentle Auger Filling | Doses coffee without compressing it | Maintains the grind structure and protects delicate oils |

| Airtight Sealing | Creates a complete barrier | Locks in freshness and locks out external contaminants |

What are the key filling technologies for preserving delicate coffee flavors?

Investing in specialty coffee is expensive, and you worry your machine will ruin it. Inaccurate dosing and harsh handling can destroy profit margins and product quality. The right technology protects your investment.

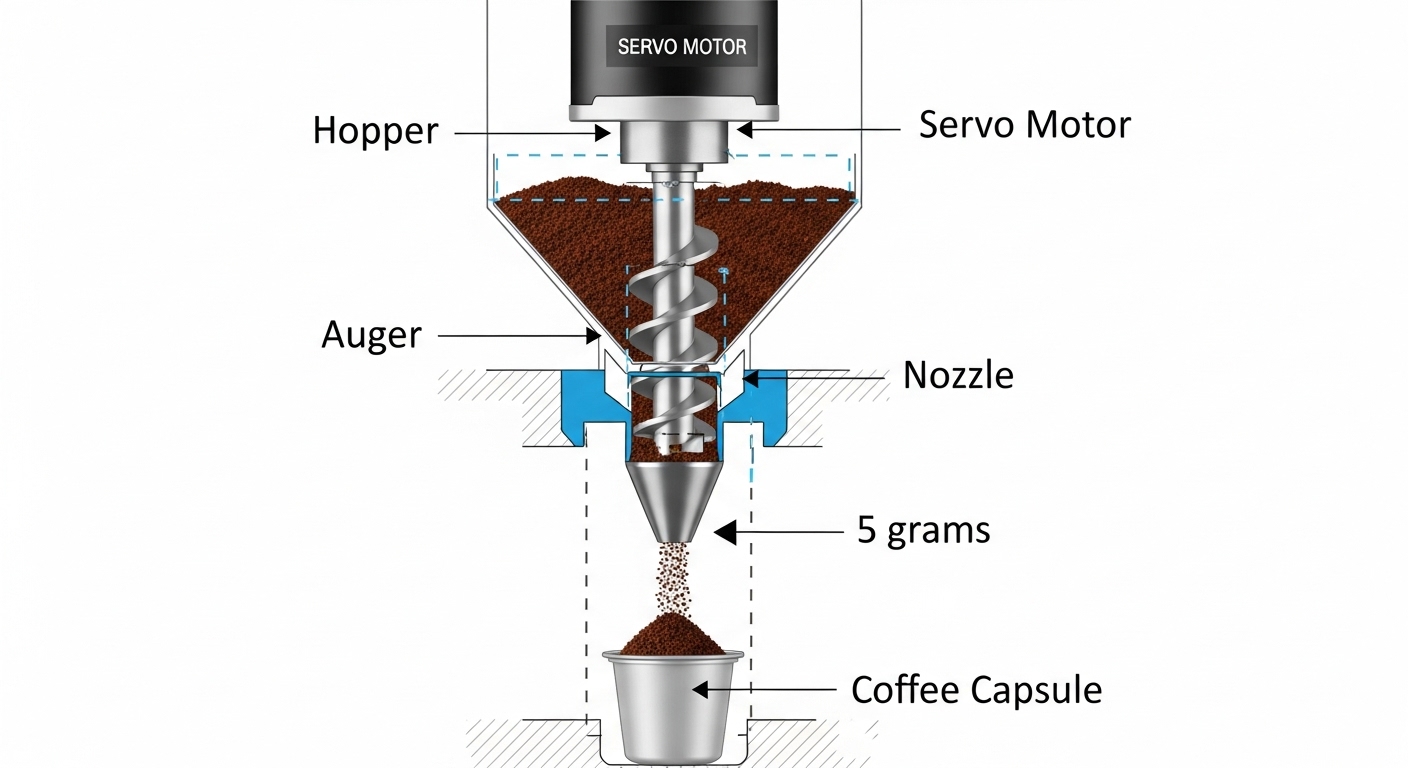

The most critical technology is the servo-driven auger filler. It provides unparalleled precision in dosing, minimizing waste and ensuring consistency. Paired with an effective de-dusting system, it maintains the coffee's purity and protects the sealing integrity of the capsule.

Precision is everything when dealing with high-value products like specialty coffee. Even a tiny variation in the amount of coffee in each capsule can change the taste of the final brew. That's why I always recommend a servo-driven auger filler. A servo motor gives you complete control over the auger's rotation—down to the fraction of a degree. This means you can dose the coffee with incredible accuracy, usually within +/- 0.1 grams. Another important detail is coffee dust. Grinding creates fine particles that can get on the rim of the capsule. If this dust is present during sealing, you won't get a perfect, airtight seal. A good machine will have a vacuum or de-dusting station right before the sealing head. It cleans the rim, ensuring a perfect seal every single time. This protects the coffee from oxygen and moisture.

Filling Technology Comparison

| Filler Type | Precision | Het beste voor | Waarom het ertoe doet |

|---|---|---|---|

| Servo Auger Filler | Erg hoog | Specialty powders, coffee | Ensures consistent taste and minimizes product waste. |

| Volumetric Cup Filler | Gematigd | Grains, free-flowing powders | Less precise, not ideal for high-value coffee. |

| Pneumatic Filler | Low to Moderate | Liquids, pastes | Not suitable for ground coffee. |

How does machine customization handle unique coffee blends and capsules?

Every client has a different coffee blend and a unique capsule design. A one-size-fits-all machine can't handle this variety, leading to production headaches. A modular, customizable machine is the answer.

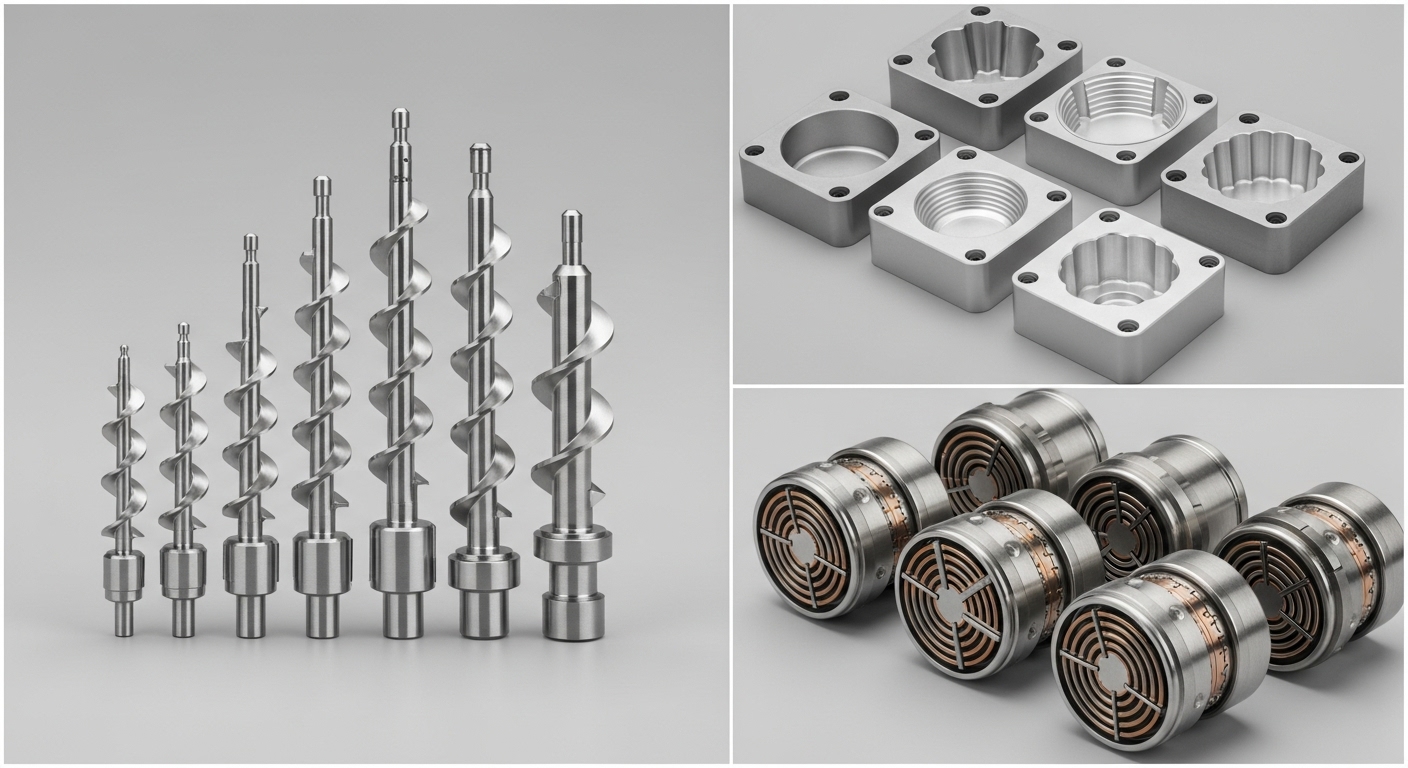

Customization is key. A modular machine design allows for interchangeable parts, like different auger screws for various grinds and custom molds for unique capsule shapes. This adaptability ensures optimal performance, whether you're filling a fine espresso grind or a coarse, flavored blend.

I remember a client from Brazil who wanted to fill a coffee blend that had tiny, dehydrated fruit pieces mixed in. Our standard auger screw was designed for pure coffee and would have crushed the fruit. We had to design a new auger with a different pitch and diameter to handle the blend gently. This is a perfect example of why customization is so important. A modular design philosophy is the foundation of our work at AFPAK. You should be able to change parts easily to fit the product. This includes the auger, the capsule holding plate, and even the sealing head. If a client wants to launch a new, uniquely shaped capsule, you shouldn't need a whole new machine. You should just need a new set of molds. This flexibility saves money and allows you to say "yes" to more projects.

Adapting Your Machine to the Product

| Production Need | Required Customization | Reason |

|---|---|---|

| Different Grind Size | Interchangeable Auger Screws | A fine espresso grind flows differently than a coarse drip grind. |

| Unique Capsule Shape | Custom Capsule Molds/Plates | The machine must hold the specific capsule securely for filling and sealing. |

| Flavored Coffee/Inclusions | Specially Designed Auger | Prevents damage to delicate inclusions like fruit or chocolate pieces. |

| Different Lid Material | Adjustable Sealing Head | Requires different temperature and pressure settings for a perfect seal. |

Conclusie

Capturing Brazil's coffee essence requires precise auger filling and nitrogen flushing. A customizable, modular machine is crucial for adapting to the diverse demands of the specialty coffee market.