The 'Samba' of Production: How Our High-Speed Fillers Orchestrate Flawless Brazilian Coffee Capsule Runs?

Are production lines full of stops and starts killing your efficiency? This chaos costs you time and money. Imagine your production line moving with the fluid, unstoppable rhythm of a samba dancer.

A high-speed coffee capsule filler achieves this flawless manufacturing through precision orchestration. Using a central control system and independent servo motors, it synchronizes every action, from filling to sealing, ensuring peak coffee capsule machine efficiency. This automated capsule production runs without missing a single beat.

This level of performance isn't just about making a machine run faster. It’s about creating a system where every component works in perfect harmony, a concept I learned to appreciate during my years on the factory floor. This mechanical ballet transforms the entire production process. Let's explore how we bring this high-speed "samba" to your production line.

How does a machine achieve the perfect rhythm of a samba dancer?

Do small, constant timing errors on your line create major production jams? These little stumbles add up to significant downtime and waste. What if every single movement was perfectly synchronized?

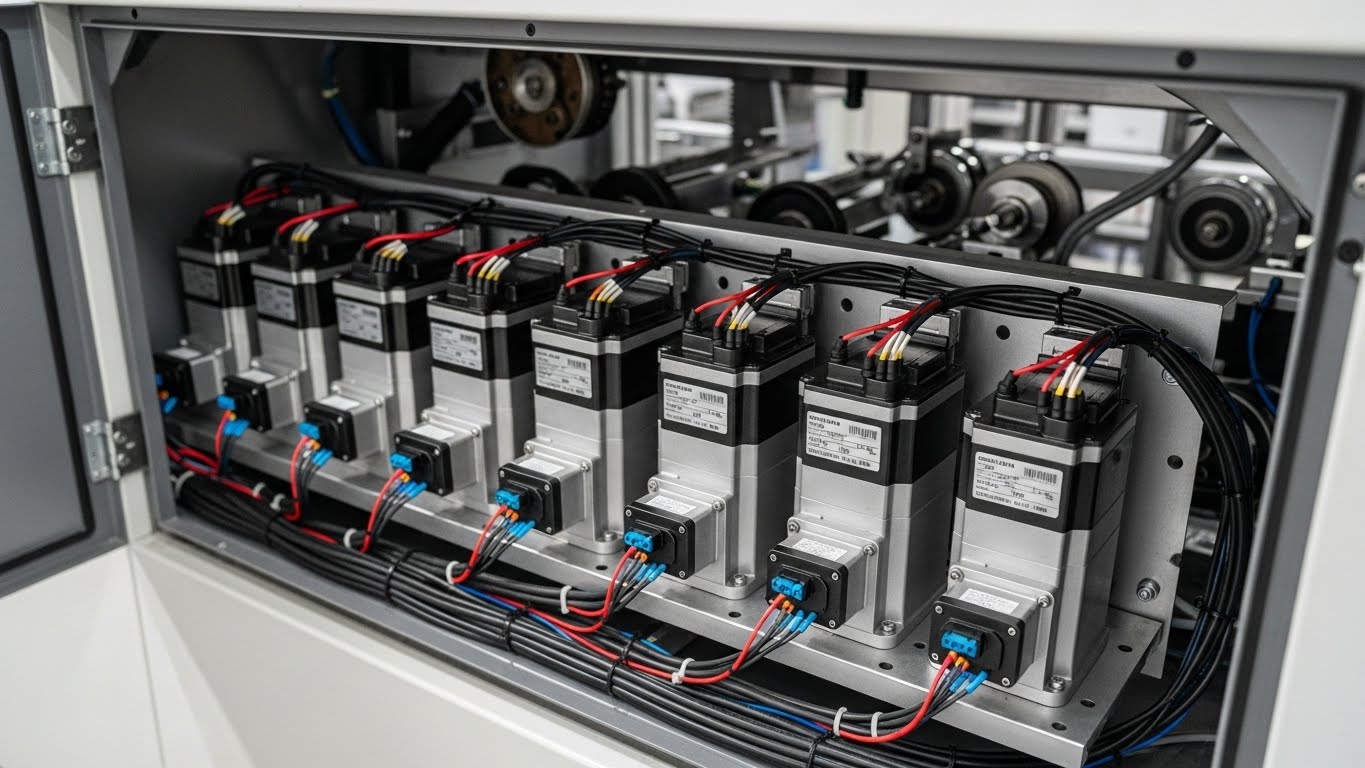

The machine's rhythm comes from a central PLC "brain" commanding individual servo motors at each station. This setup ensures every part—capsule dropper, filler, sealer—moves in perfect, coordinated time. This digital conductor creates a flawless, high-speed beat for automated capsule production.

When I first started building machines, many systems used a single, large motor with a series of mechanical cams and gears. It worked, but it was rigid. If you wanted to change one small thing, you had to re-engineer the whole mechanical line. It was like teaching a whole dance troupe a new step for just one dancer. Today, the philosophy is completely different, and it's something designers like Jeffree can truly leverage. It’s about digital precision and flexibility.

The Brain: Centralized PLC Control

At the heart of our high-speed coffee capsule filler is the Programmable Logic Controller (PLC). I think of it as the band's conductor. It doesn't just start the music; it dictates the tempo and ensures every instrument comes in at the exact right moment. The PLC sends thousands of signals per second to orchestrate the entire production flow with millisecond accuracy.

The Dancers: Independent Servo Motors

Each station on the machine is a dancer, and each one has its own servo motor. This is the real game-changer.

- The capsule dropper gets its own motor.

- The auger filler for the coffee powder has its own motor.

- The film sealer has its own motor.

This independence is key. If the delicate Brazilian coffee powder requires a slightly slower, more gentle fill to preserve its aroma, the PLC can command the auger filler's servo to adjust instantly, without slowing down the sealing station. This is impossible with an old-style single-motor machine.

| Recurso | Single-Motor System | Multi-Servo System |

|---|---|---|

| Ao controle | Mechanical Cams | Digital PLC Signals |

| Flexibility | Low (Hard to adjust) | High (Instantly adjustable) |

| Precision | Bom | Exceptional |

| Velocidade | Limited by slowest part | Optimized for each station |

This system creates a smooth, continuous flow—a true production samba.

Can you really increase speed without sacrificing the quality of each coffee capsule?

Are you forced to choose between speed and quality? Pushing for faster output often results in sloppy fills and failed seals, creating expensive waste. How can you produce more, faster, with zero defects?

Yes, by using smart sensors and real-time feedback loops. Our high-speed fillers integrate in-line checkweighers and vision systems that monitor every capsule. The machine instantly self-corrects for any deviation, ensuring flawless manufacturing quality even at top speeds.

I remember visiting a potential client who was running a competitor’s machine. They were proud of its speed, but as we watched, I saw their operator pulling out poorly sealed capsules every minute. Their actual output of good products was much lower than the machine's advertised speed. They were running fast, but they were stumbling. True coffee capsule machine efficiency isn't just about speed; it's about the speed of perfect production. That’s where integrated quality control becomes non-negotiable.

Precision Filling with Feedback

The quality of a coffee capsule starts with the fill. Our machines use a servo-driven auger filler, which we can control with extreme precision. We program it to dispense exactly 5.5 grams of coffee, for example. But we don't just trust it to do that every time.

- Fill: The auger dispenses the coffee powder.

- Weigh: Immediately after, an in-line checkweigher weighs the capsule.

- Adjust: This weight is sent back to the PLC. If it was 5.51 grams, the PLC tells the auger servo to rotate just a fraction of a degree less on the next cycle. This happens continuously, ensuring every capsule is perfect.

Sealing with a Watchful Eye

A bad seal is the most common failure point. We use a vision system—a small, high-speed camera—to solve this. It sits right after the sealing station and inspects every single capsule lid.

| Quality Check | Technology Used | Propósito |

|---|---|---|

| Fill Weight | In-Line Checkweigher | Guarantees consistent coffee dose. |

| Seal Integrity | High-Speed Vision System | Detects wrinkles, misalignments, or foreign particles. |

| Capsule Placement | Proximity Sensors | Ensures capsule is present and correctly positioned. |

If the vision system detects even a tiny flaw, that capsule is automatically pushed off the line by a puff of air. This ensures that only 100% perfect products make it into the final box. This is how you run a flawless manufacturing samba.

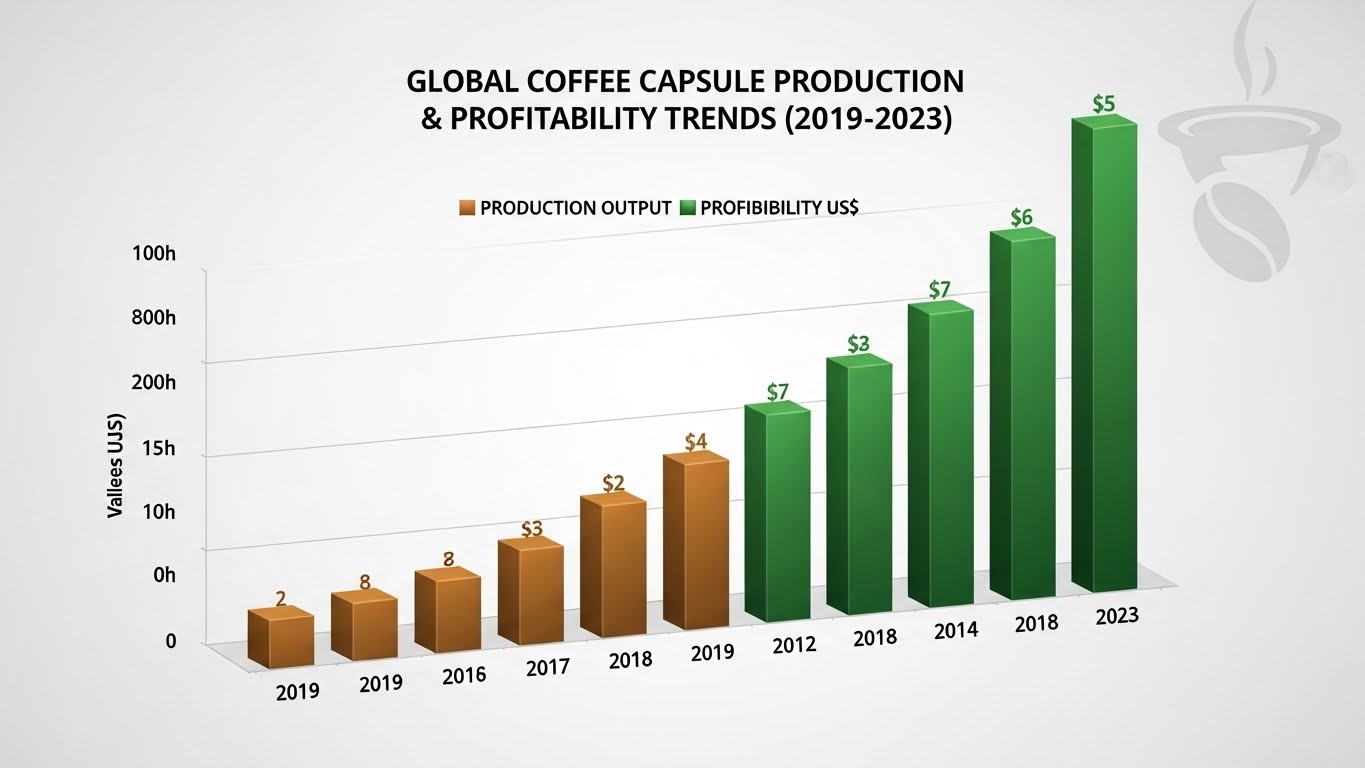

What does this production orchestration mean for your business's bottom line?

Are high waste rates and production stops eating away at your profits? Downtime is a silent killer, and an inefficient line limits your ability to take on bigger, more profitable orders.

This level of production orchestration directly increases profit. Greater machine efficiency leads to higher output per shift. Near-zero waste cuts material costs. This reliable automated capsule production allows you to confidently accept large contracts, fueling your company's growth.

I've seen the impact of this firsthand. A few years ago, I helped a family-owned coffee roaster in Brazil upgrade their old, slow equipment. They had amazing coffee, but their production capacity was holding them back. They were hesitant about the investment, so we sat down and looked at the real numbers. For a designer like Jeffree, understanding this business impact is just as important as understanding the mechanical design. The machine isn't just a machine; it's a tool for growth.

Tripling Output

Their old line produced about 35-40 capsules per minute and required two operators to keep it running smoothly. Our machine allowed them to run consistently at 120 capsules per minute with just one operator overseeing the process. They didn’t need to build a new facility or hire a second shift; they just made their existing time three times more productive.

Slashing Waste Costs

More importantly, their waste rate from underweight fills and bad seals was nearly 4%. At their volume, that was thousands of dollars in premium coffee and packaging materials thrown away each month. Our system, with its integrated quality control, brought that waste rate down to under 0.5%.

| Métrica | Before AFPAK Machine | After AFPAK Machine | Financial Impact |

|---|---|---|---|

| Saída | ~2,100 Capsules/Hour | 7,200 Capsules/Hour | +242% Throughput |

| Waste Rate | 4% | <0.5% | ~88% Reduction in Waste Cost |

| Labor | 2 Operators | 1 Operator | 50% Labor Savings |

The numbers speak for themselves. Within a year, the machine had paid for itself not just in increased output, but in savings. More importantly, it gave them the production power to land a contract with a national distributor, something that was previously just a dream. That is the true power of a perfectly orchestrated production line.

Conclusão

Ultimately, our machines provide more than just speed. They bring a consistent, predictable, and highly profitable rhythm to your factory, turning your production line into a perfectly coordinated and powerful performance.