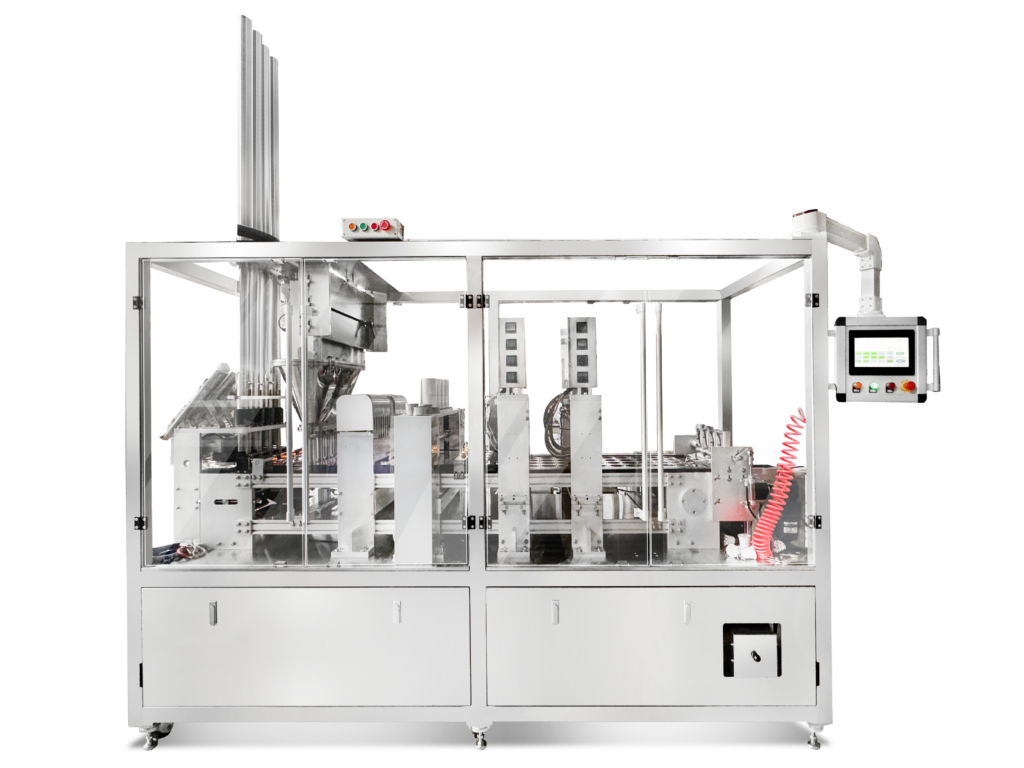

Are you looking for more efficient k cup production equipment for your factory? If so, you definitely need an AFPAK H4 K cup filling sealing machine!

k cup filling sealing machine is a professional coffee capsule filling machine that allows you to easily make coffee capsules that match your taste and needs. You only need to prepare coffee powder, empty capsules, and aluminum foil lids, and then follow simple steps to produce high-quality coffee capsules in a short time.

This machine can produce 160-200 k cups per minute, which can greatly improve your production efficiency.

It has a wide range of applications. It can not only produce coffee products, you can use it to produce tea, milk powder, instant powder, and other types of powder granular products

At the same time, we have made a lot of user-friendly designs to make it very easy to clean and maintain.

H4 k cup filling sealing machine has the following advantages:

Efficient: The H4 k cup filling machine can fill 40-50 coffee capsules per minute for each lane, which greatly improves production efficiency and saves costs.

Accurate: The k cup filling machine adopts an advanced auger filling system and control system, which can accurately control the weight and sealing quality of each capsule, ensuring the consistency and stability of the coffee capsules.

Easy to use: The H4 k cup filling sealing machine is easy to operate, just press a few buttons to complete the entire filling and sealing process. The H4 k cup filling and sealing machine is also equipped with a touch screen and fault prompt function, allowing you to monitor and adjust the equipment status at any time.

Hygienic: The H4 k cup filling sealing machine adopts stainless steel material and sealing design, which prevents dust and bacterial contamination and ensures the hygiene and safety of the coffee capsules.

If you want to purchase or know more about the H4 k cup filling sealing machine, please contact us. We will provide you with professional coffee solutions and high-quality after-sales service.

k cup filling sealing machine, lets you produce every cup of coffee easily!

Functions of H4 k cup filling sealing machine

AFPAK H4 is a well-known K Cup filling and sealing machine with multiple functions designed to increase production efficiency and ensure product quality. Here are some of the key features of the AFPAK H4 K Cup filling and sealing machine:

- Automatic filling: Equipped with an automatic filling function, it can fill K Cup capsules quickly and accurately, improving production efficiency.

- Sealing system: Equipped with an efficient sealing system to ensure that the K Cup capsule can be perfectly sealed after filling to maintain the fresh taste of the coffee.

- Intelligent control panel: Equipped with an advanced intelligent control panel, it is convenient for operators to control and monitor the production process and ensure the stable operation of the production line.

- Customized filling: Supports customized filling solutions, which can be flexibly adjusted according to the needs of K Cup capsules of different specifications and capacities.

- High-precision sensor: Equipped with high-precision sensors to ensure that each K Cup capsule can accurately complete the filling and sealing process, ensuring product quality and consistency.

- Easy to maintain: The design is simple and easy to maintain, allowing operators to easily perform daily care and maintenance, improving the stability and reliability of the equipment.

- Compact design: The compact and efficient design makes it suitable for various production environments, saving space and improving the overall efficiency of the production line.

- Reliable after-sales service support: Provide reliable after-sales service support, including training, maintenance and parts replacement, to ensure that customers receive all-round support and services during use.

The AFPAK H4 K Cup filling sealing machine can meet the needs of coffee production of different sizes and types through its multiple functions, making it an ideal choice for coffee manufacturers.

Specifications of H4 K cup filling sealing machine

Below is a list of possible parameters for the AFPAK H4 K Cup filling machine. Note that these parameters may vary with different configurations and customization options.

| Especificações | Descrição |

|---|---|

| Cups suit for | K Cup (51mm diameter 8-13 grams filling volume) |

| Capacidade | 9600-12000 cups/hour |

| consumo de nitrogênio | 300L/min |

| Consumo de ar | 950L/min |

| Poder | 3 phs 220V, 50/60HZ |

| Consumo de energia | 6Kw, 20A |

| Precisão de enchimento | ±0,2g |

| Sealing Type | Hot seal (Ultrasonic seal available) |

| Control system | PLC control system |

| Faixa de enchimento | 5-20 grams |

| Filling hopper material | Stainless steel(SUS304) |

| Dimensões | 4500*1200*3000 mm |

| Peso | 1500 Kgs |

| Control screen | Touchscreen (English/Chinese Languages) |

| Electrical brands | Schneider/Omron/Airtac |

| Manutenção | Clean and lubricate regularly |

| Suit for | Medium and Large coffee companies |

Check more other k cups filling sealing and packaging machines options here