How Can Advanced Sealing Technology Unlock the True Flavor of Brazilian Coffee in Capsules?

Your Brazilian coffee loses its rich flavor inside the capsule. This disappoints customers. But what if the seal is the key to unlocking that perfect taste?

Advanced sealing technology creates an airtight barrier, preserving the coffee's delicate volatile compounds. During brewing, a perfect seal ensures optimal pressure and uniform water distribution. This extracts the full spectrum of flavors, from nutty to chocolatey, that makes Brazilian coffee special.

It's clear that a good seal is more than just closing a lid; it's about protecting the very soul of the coffee. But how exactly do different sealing methods impact the extraction process? I've spent years obsessing over this detail, and the science behind it is fascinating. Let’s dive deeper into the mechanics and see how you can apply this to your production line. It's a small change that makes a huge difference.

How Does Sealing Pressure Directly Impact Brazilian Coffee's Flavor Profile?

Inconsistent sealing pressure leads to weak capsules. This results in watery, bad-tasting coffee. Let's see how controlling this pressure guarantees a perfect brew every time.

Optimal sealing pressure ensures the lid is perfectly bonded to the capsule body, preventing pressure loss during brewing. It forces hot water to saturate the coffee grounds evenly, extracting balanced notes of caramel and nut. Too little pressure causes leaks; too much can damage the foil.

The relationship between pressure, the seal, and the final taste is something I've studied for years. It's a delicate balance. When I first started AFPAK, one of our clients was having trouble with their capsules. Customers complained about weak coffee. We found their machine applied uneven pressure across the sealing head. Some capsules leaked, while others were fine. This inconsistency was killing their brand reputation. We helped them calibrate their system, and the problem vanished.

The Role of Consistent Pressure

Consistent pressure creates a hermetic seal. This means no oxygen gets in, and no aroma gets out. During brewing, this perfect seal allows pressure to build inside the capsule, typically to around 9-12 bars. This pressure is essential. It forces hot water through the compacted coffee grounds at the right speed. This process, called extraction, pulls out all the desirable oils and solids that create the rich body and crema characteristic of a great espresso shot from Brazilian beans.

Risks of Improper Pressure

Getting the pressure wrong can ruin the coffee. I've laid out the most common outcomes in a simple table. As a designer like Jeffree, understanding these parameters is crucial for building a reliable packaging process.

| Sealing Pressure | Seal Quality | Brewing Result | Flavor Impact |

|---|---|---|---|

| Too Low | Weak bond, micro-leaks | Pressure loss, water channeling | Watery, under-extracted, sour |

| Optimal | Strong, hermetic | Even water flow, full saturation | Balanced, rich, full-bodied |

| Too High | Damaged foil, warped cup | Inconsistent extraction, potential blockage | Bitter, over-extracted, harsh |

Why Are Material Choices Crucial for Sealing and Preserving Coffee Freshness?

The wrong foil lets oxygen in, making your coffee taste stale. This ruins the customer's experience. Let's explore the materials that lock in freshness from day one.

The right materials, like multi-layered aluminum foils, create a superior oxygen and moisture barrier. This is vital for preserving the delicate oils and aromatic compounds in coffee. These materials also ensure a clean puncture during brewing for consistent water flow and flavor extraction.

I remember a project where we were trying to package a single-origin Brazilian coffee with very distinct chocolate notes. The client initially chose a cheaper, thinner foil to save costs. After just a few weeks in storage, the coffee tasted flat. The delicate chocolate aroma was gone. Oxygen had penetrated the weak barrier and degraded the coffee oils. We switched them to a high-quality, multi-layer aluminum lid, and the difference was night and day. The flavor remained rich and vibrant for over a year. It taught me a valuable lesson: never compromise on barrier materials.

The Aluminum Foil Standard

Aluminum is the gold standard for a reason. It has an almost zero transmission rate for oxygen and moisture. It completely blocks light, which can also degrade coffee quality over time. This makes it the best choice for long-term preservation of sensitive products like coffee. For Brazilian beans, known for their low acidity and sweet, nutty profiles, protecting them from oxidation is everything.

Exploring Lidding Film Layers

Most high-performance lids are not just a single layer. They are a complex laminate designed for specific functions.

- Outer Layer (e.g., PET/PBT): This provides puncture resistance and a surface for printing high-quality graphics.

- Mid-Layer (Aluminum): This is the core barrier layer, protecting against oxygen, moisture, and light.

- Inner Layer (Heat Seal Lacquer): This is the layer that actually bonds to the capsule rim. It's designed to melt at a specific temperature and create a strong, peelable seal.

Understanding these layers helps you specify the right material for your product.

How Can Advanced Sealing Technology Adapt to Diverse Capsule Materials and Designs?

New capsule materials are exciting, but your old sealer can't handle them. This stops innovation. Let's look at technology that adapts to any material, from plastic to compostable.

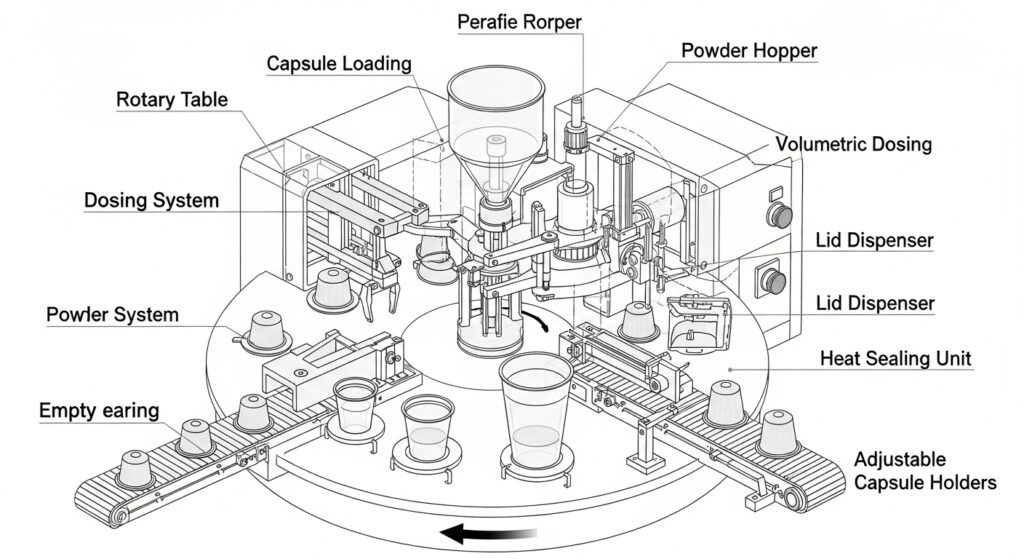

Advanced sealing systems use precise temperature and pressure controls. Servo-driven motors and smart sensors allow the machine to adjust parameters instantly. This ensures a perfect seal on various materials like PP, PLA, or aluminum, accommodating different rim designs without compromising integrity.

A while back, a designer, let's call him Jeffree, came to us. His company was a leader in sustainability and wanted to switch their entire coffee capsule line to compostable PLA materials. Their existing machines were designed for standard PP plastic and just couldn't get a consistent seal on the PLA capsules. The sealing temperature was too high, causing the PLA rims to warp and fail. We worked with him to integrate one of our newer sealing stations into his line. Our system's precise temperature control and adjustable pressure settings solved his problem in a week. He could finally innovate without limitations.

Temperature Control is Key

Different plastics have very different melting points. A temperature that perfectly seals a polypropylene (PP) capsule will melt and deform a polylactic acid (PLA) one. Modern sealing machines use PID controllers to maintain the sealing head temperature within a very tight range, often +/- 1°C. This precision allows you to create the perfect bond without damaging the capsule, no matter the material.

Adapting to Capsule Rim Geometry

The shape of the capsule rim is also critical. Some have a flat top, while others have a slight groove. The sealing head must be custom-machined to match this geometry perfectly. This ensures that pressure is applied evenly across the entire surface. Our machines use servo-driven technology, which allows us to control not just the final pressure but also the speed and force profile of the sealing motion. This level of control is essential for new and unconventional capsule designs.

| Capsule Material | Sealing Temperature | Sealing Pressure | Key Consideration |

|---|---|---|---|

| PP (Polypropylene) | High (≈200-220°C) | Moderate | Very common, stable, wide sealing window |

| PLA (Polylactic Acid) | Lower (≈150-170°C) | Gentle | Compostable, very sensitive to heat |

| Aluminum | Varies with lacquer | High | Excellent barrier, requires strong bond |

Conclusion

A perfect seal is not just a final step. It is the key to preserving and extracting the true, rich flavor of your Brazilian coffee in every single capsule.