K cup Filling Packaging Solutions

Provider of one-stop solutions for K-Cup filling machines and box packaging machines with a capacity of 50-300 cups per minute.

* Quotation within 24 hours

* Professional and efficient

* Quality first

* Reasonable prices.

* The choice of over a hundred users.

Get your Solutions today

CUSTOMIZED SOLUTIONS AVAILABLEQuickly and successfully produce your own K-Cup products now!

AFPAK will help you produce high-quality K-Cup products in the shortest time.

The ideal manufacturer of your K Cup filling and Sealing Machines and packaging machines

How can you quickly produce your own K-Cup products? How can you improve your K-cup production efficiency? AFPAK offers you the best K cup filling sealing packaging solutions.

Features of AFPAK’s K cup filling sealing packaging machines:

- USA maintenance center

- Easy to use and maintain

- Fast speed: 50-400 cpmin

- Easy changeover to produce different capsules

- Small layout

- Save Labors: 1-2 people enough to run machines

- Fast response: 4-8 hours response for any questions

- 14+ years manufacturing experience

CALL 859-813-2814 Now to get a quick solution

50-300

K cups per minute

300+

K cups machines have been produced

CERTIFICATIONS

CE 2014/35/EU

CE 2006/42/EC

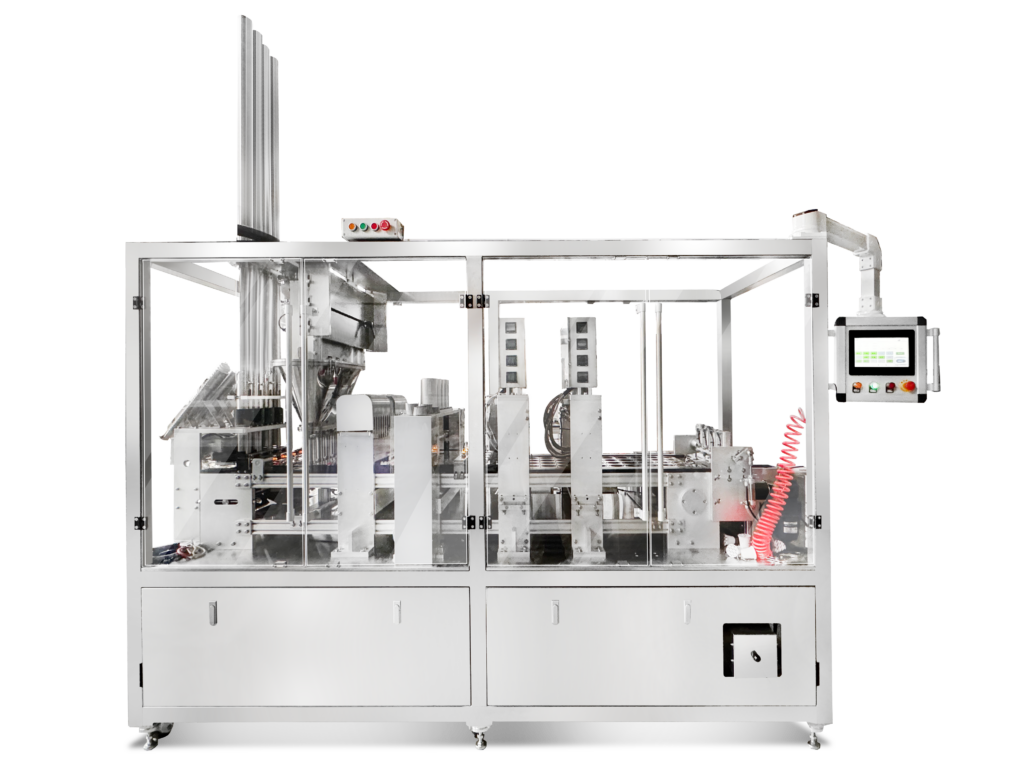

RN1S Model

K Cup Filling Machine

50-70 cpmin ★ Best Seller ★

- Small layout: Unrestricted by space, production can occur anywhere

- Fast Changeover: Produce K-cups and Nespresso capsules with one machine

- Easy to use: Learn to use the equipment in less than 30 minutes

- Quick Delivery: Delivery within four weeks of placing an order.

Call 859-813-2814 for more details

Or leave message here:

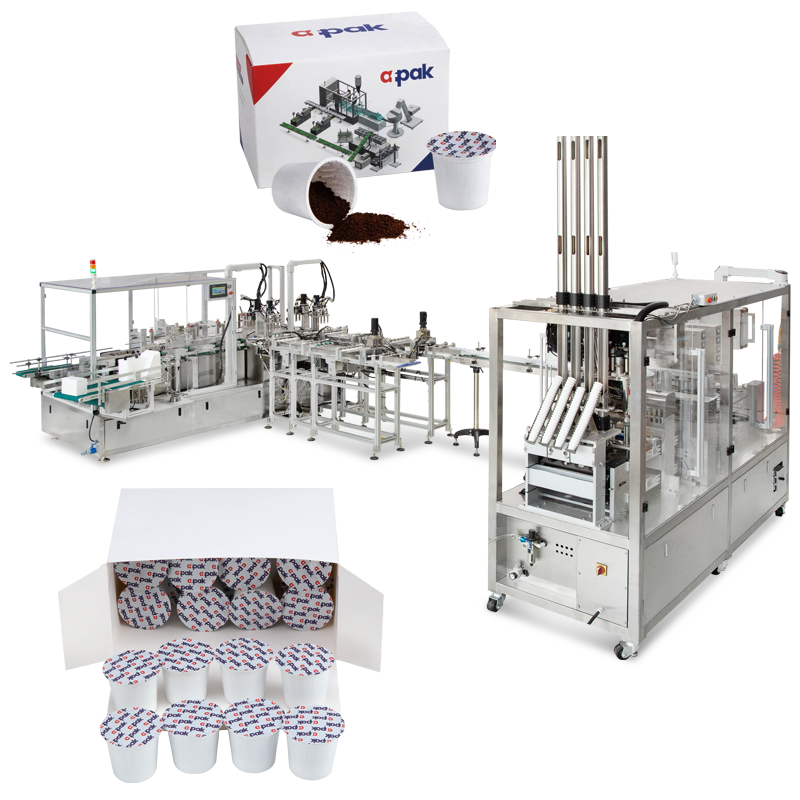

HB410 K-cup Filling Sealing Packaging Machine

200-400 cpmin ★ New Arrival ★

- High Output: A powerful tool for increasing production and expanding capacity.

- Fully Featured: Fill, seal, and cartoning all in one machine.

- High Quality: Globally renowned electrical components combined with high-strength mechanical parts ensure high efficiency and minimal downtime.

- Online Service: Available 24/7 to address any production concerns you may have.

Call 859-813-2814 for more details

Or leave message here:

Wholesale Kcups Packaging Supplies

We have both welded/separated k cups

The out cups use PP#5 recyclable materials and inside filter use paper or fabric filters

also have 2.0 compatible sealing lids materials with custom designs printing, and packaging boxes for pack 12-18-24-36-96 cups

Can Keep your coffee for at least 12 months

Small MOQ, Low Price! Quick Delivery!Order now!

Diverse Array of aFPAK's K Cup Filling sealing Packaging Machines

HB410 K cup Filling Packaging Machine

HB410 K Cup filling packaging machine is AFPAK’s most powerful k cup filling, sealing, and packaging equipment at present. It

H4 K cup Filling Sealing Machine 2024 New Version

Are you looking for more efficient k cup production equipment for your factory? If so, you definitely need an AFPAK

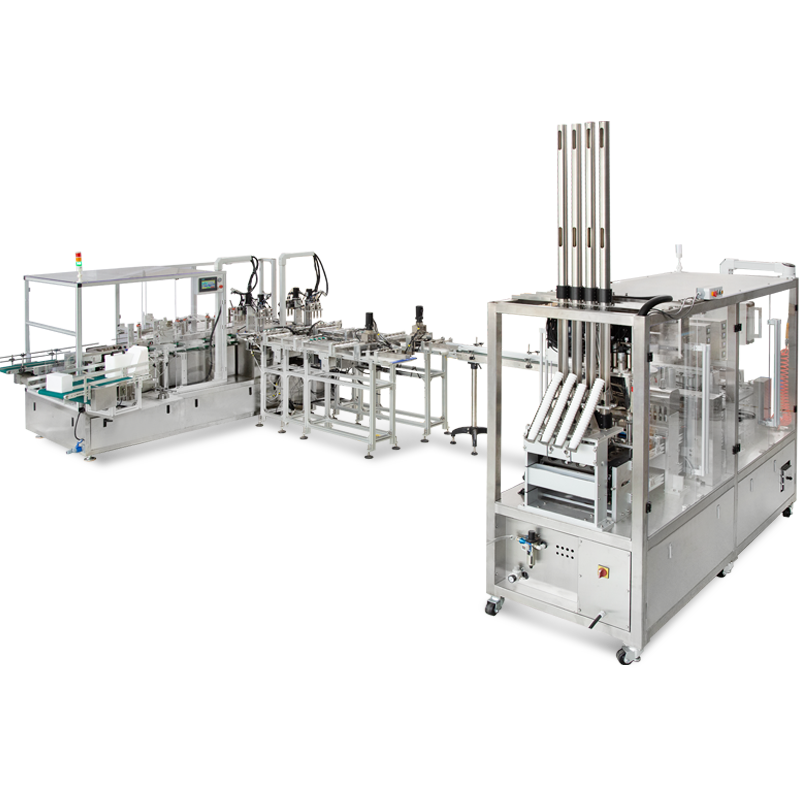

80-400 CPMIN K cup filling packaging machine

AFPAK’s H series K cup filling packaging machine is ideal for k-cups filling, sealing, nitrogen flushing, and cartoning production. This

H1 K cup filling sealing machine

The H1 K cup filling sealing machine is a quick and entry-level solution specializing in the production of filling and

AF-RN120 Rotary K cup filling machine

The AF-RN120 is our latest generation of Rotary k cup filling machine, based on the RN1S, we have made some

coffee capsule filling sealing packaging machine

AF-H410 Coffee capsule filling sealing packaging machine is the solution to fill coffee in coffee capsules, close and pack with Nitrogen

Semi Auto Filler and Sealer machine for Nespresso, K cup, Dolce Gusto, lavazza capsules

The semi-auto XBZD95S filler and sealer machine is a device that can help novices and laboratories to complete filling and

2024 New Quality k cup manufacturing equipment

AF-RN1S K cup manufacturing equipment is a quality solution to fill coffee, cocoa, and milk powder in K cups and K

BZD95 K cup Sealing Machine Quality solution for startup business

BZD95 K cup sealing machine is a professional lab-table solution for customers to seal k-cups. A good k cup sealer

4800 cph K cup filling sealing machine

AF-H2 K cup filling sealing machine is the solution to fill coffee in K cup / K shot capsules, seal, and

Coffee capsule filling and sealing machine 2024 New upgrades

RN1S Coffee Capsule Filling and Sealing Machine is a simple, reliable, and robust packaging solution for coffee capsules, this machine

AF-RK1 K cup filling sealing machine

AF-RK1 model is full automatic k cup filling sealing machine which can produce up to 25 CPM with filter inserting option.

Rotary

K CUP FILLING SEALING MACHINE, 2024 Quality Choose

Efficiency redefined! Experience convenience and peace of mind with AFPAK’s RN1S K cup filling sealing machine. Transforming your coffee production,

Advantages of AFPAK k cup filling packaging machines

scalability

All our machines are capable of filling various materials and accommodating production with different cup sizes

Stability

We meticulously select materials and electronic components, with our designed and manufactured with extensive experience, ensures a stable and reliable user experience for you.

safety

We not only ensure the safety of your investment but also prioritize your operational safety.

Economical

AFPAK's machines are more cost-effective option for filling and packing k cups. No need to replace or do daily maintenance.

Recognized by over 50 coffee companies across the USA.

From New York to Los Angeles, from Miami to Fargo, AFPAK machines are already operating successfully in over 50 coffee company factories. Praised for their user-friendly operation and reliable performance, our equipment earns high marks from satisfied customers. Join this thriving operational ecosystem and make your coffee dream a reality.

Quality & Fast delivery

Your K cup filling packaging machines will produced here

As the top 1 manufacturer of k-cup filling and packing machine in China, we have accumulated 14+ years of production experience, served more than 100 coffee companies and helped them to grow by leaps and bounds.

We have a strong team of engineers who can quickly customize a complete K cup filling and packaging line for you; our highly trained sales team can give quick and precise answers.

We have been designing and manufacturing machines from the customer's point of view with the aim of "producing higher quality equipment for our customers", which is also well received by our customers.

If you have a need to produce single serve k cup products, please feel free to contact AFPAK.

AFPAK is great! We customized our K cup filling machines for our business, AFPAK was very responsive, and they made sure that we got what we need!

Sebastian Enrique

Production Manager, Mia Coffee Company

Frequently Asked Questions

AFPAK’s K-Cup filling and sealing machines provide coffee companies with an efficient and precise solution for packaging ground coffee into single-serve cups, sealed with aluminum foils. This system enhances product quality while saving labor.

These machines can fill K-Cups with coffee, cocoa, tea, milk powder, and more, accommodating 8-13 grams per single-serve cup.

The K-Cup packaging machine is sometimes also referred to as the K-Cup cartoning machine.

This machine can be customized to package different configurations, such as 2*3*2 (12 counts), 3*3*2 (18 counts), and 4*3*2 (24 counts) cups per box. or 50 cups packaged in bulk per box, etc

Yes, To provide faster and more accurate quotes for you, please let us know:

1- What kind of capsules do you want to produce? K-cups? Nespersso? Dolce Gusto? or others

2- What functions do you want to have on your machine? Filling? Sealing? Cartoning?

3- How many capsules per min do you want to produce?

4- What do you want to fill inside the capsules? How many grams?

Once we get your inquiry, normally we will response in 4-8 hours

For newly launched or small-scale coffee companies, if you need to produce K-Cups or other coffee capsules, we recommend the RN1S model K cup filling sealing machine for the following reasons:

- Small Production Capacity: The RN1S machine offers adjustable speeds ranging from 11 to 60 cycles per minute.

- High Precision: Both filling and sealing precision of the RN1S reach world-leading levels

- Compact and User-Friendly: Through multiple updates and iterations, you can learn to use and maintain the machine within just one hour.

- High Quality: The RN1S is equipped with electrical components from renowned brands such as Schneider, Omron, and Airtac. Coupled with solid craftsmanship, it ensures stable and durable production.

You can inquiry RN1S model K-cup filling sealing machine now!

Yes!

For the U.S. market, we offer door-to-door shipping services, including sea and land transport to your factory doorstep, as well as customs clearance and payment of import duties.

If you require this service, please provide your factory address, and we will contact our logistics company for a quote.

Typically, the delivery time to your doorstep is 8-10 weeks.

For other markets, we provide shipping services to the nearest port, so please also provide your company address for us to inquire about shipping costs.

Yes!

The main feature of AFPAK filling packaging equipment is its ability to be compatible with multiple cup sizes, requiring only faster replacement parts.

Generally, for the RN1S model, the replacement time for parts is within 30 minutes, while for the H series, it varies from 1 to 2 hours.

However, this feature is optional and not mandatory, so please inform us before placing an order if production of multiple cup sizes is required, so that we can customize the equipment accordingly.

AFPAK also provides high-quality empty K-Cups and sealing films. With low minimum order quantities and competitive pricing, we offer door-to-door delivery service. Feel free to contact us for price inquiries.

The Empty k cups MOQ is 100,000 pcs, price is 0.055USD/pc with door to door shipping

YES!

You can send us your design drafts, and we will examine the printing colors and provide design suggestions. Some designs may not print clearly if they are too small.

Additionally, we use high-speed professional printing equipment, so the minimum order quantity for a single design draft is 300,000 pieces.

For new designs, we charge a plate-making fee of $100 per color for the first time. The entire production cycle takes 20-25 days.

YES!

You can send us your design drafts, and we will examine the printing colors and provide design suggestions.

The MOQ for each design of the cartons are 3000 pcs

The entire production cycle takes 20-25 days.