What Makes a Coffee Capsule Filling Sealing Machine Essential for Commercial Production?

Are you struggling with inefficient coffee capsule production? Manual filling and sealing processes waste time, compromise quality, and limit your output potential. Many businesses face these exact challenges when scaling up.

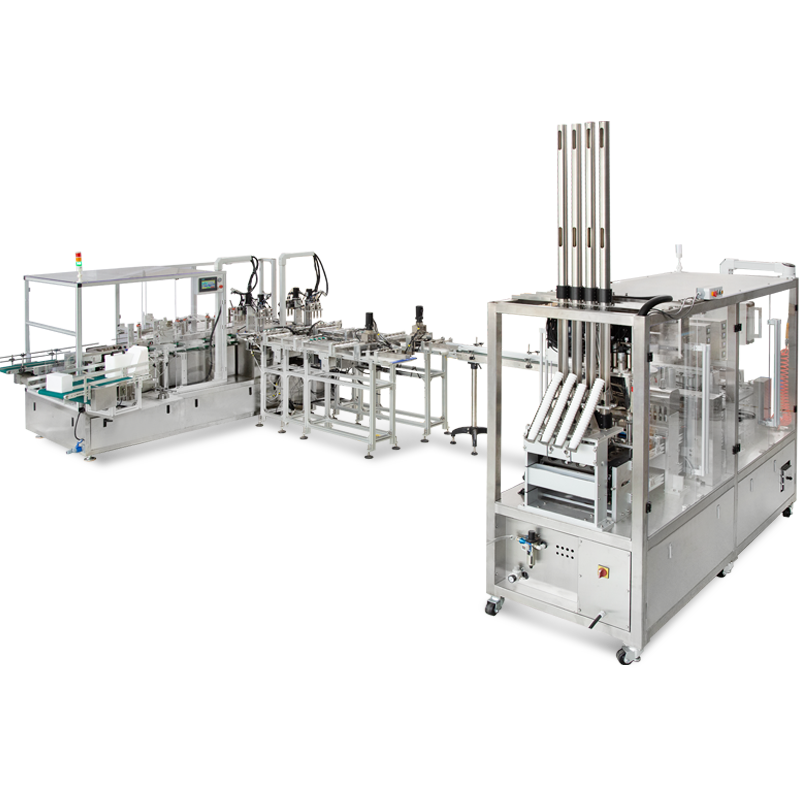

A coffee capsule filling sealing machine automates the entire process of measuring, filling, and hermetically sealing coffee capsules at high speeds. These machines combine precision dosing technology with reliable sealing mechanisms to ensure consistent product quality while significantly increasing production capacity.

Let's explore why these machines have become indispensable in commercial coffee production. If you're considering upgrading your production line or entering the coffee capsule market, understanding these systems will help you make informed decisions about your equipment investments.

How Does an Automatic Coffee Capsule Filling Machine Improve Production Efficiency?

Production bottlenecks can devastate your coffee business. Manual filling is slow, labor-intensive, and prone to inconsistencies that customers notice immediately. Your profit margins suffer with every inefficient process.

Automatic coffee capsule filling machines improve efficiency by processing thousands of capsules per hour with minimal human intervention. Modern systems feature multi-lane designs with precision dosing systems that maintain consistent fill weights within ±0.1g, ensuring product uniformity while reducing labor costs by up to 80%.

When I first upgraded from semi-automatic to fully automatic filling systems, the transformation was remarkable. One machine I installed for a client increased their production capacity from 600 to 3,600 capsules per hour with just one operator. The technology behind these efficiency gains comes from several key innovations.

Production Speed Comparison

| Machine Type | Capsules Per Hour | Operators Required | Cost Efficiency |

|---|---|---|---|

| Manual | 100-200 | 2-3 | Low |

| Semi-Automatic | 500-1,000 | 1-2 | Medium |

| Fully Automatic | 2,000-6,000 | 1 | High |

| Industrial Automatic | 6,000-30,000 | 1-2 | Very High |

The return on investment typically becomes apparent within 6-12 months for most commercial operations. Modern machines also incorporate servo-motor technology that allows for quick format changes, meaning you can switch between different capsule types or coffee varieties with minimal downtime. This flexibility is crucial for businesses producing multiple SKUs or seasonal offerings.

Another efficiency gain comes from integrated quality control systems that automatically reject defective capsules, reducing waste and ensuring only perfect products reach your customers. These systems use various detection methods including weight verification, vision systems, and leak detection to maintain quality standards.

What Features Should You Look for in a Commercial Coffee Capsule Sealing Machine?

Inconsistent seals lead to oxidation, flavor loss, and disappointed customers. Poor sealing technology creates leaks and rejected products, while manual methods can't maintain the precision needed for today's competitive market.

Commercial coffee capsule sealing machines should feature multiple sealing technologies (heat, ultrasonic, or pressure), oxygen-displacement systems, and precise temperature controls. Quality models maintain sealing consistency across high-speed operations (3,000+ units/hour) and include automatic detection systems that identify and reject improperly sealed capsules.

The sealing process is perhaps the most critical aspect of coffee capsule production, as it directly impacts shelf life and flavor preservation. I've worked with clients who switched from heat sealing to ultrasonic technology and saw their product shelf life extend by several months while reducing material costs.

Sealing Technology Comparison

| Sealing Method | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Heat Sealing | Cost-effective, reliable | Slower, potential heat damage | Medium volume production |

| Ultrasonic Sealing | Fast, strong seals, no heat damage | Higher initial cost | High-volume, premium products |

| Pressure Sealing | Works with various materials | May require specific lid designs | Specialized capsule formats |

| Nitrogen Flush Sealing | Extended shelf life | Additional complexity | Premium coffee products |

Modern sealing machines incorporate multiple inspection points to verify seal integrity. These may include vacuum testing, vision systems that check for proper lid placement, and even pressure testing in more advanced models. The data collected from these quality checks can be integrated with your production management systems for continuous improvement.

Material compatibility is another crucial consideration. The best commercial machines offer adjustable sealing parameters to work with different lid materials, from aluminum to biodegradable alternatives. This flexibility future-proofs your investment as sustainability requirements evolve in the coffee industry.

How Do Integrated Filling and Sealing Systems Maximize Production Value?

Separate filling and sealing operations create inefficiencies, require more floor space, and increase the risk of contamination. Disconnected systems mean more transfer points, more potential errors, and lower overall productivity.

Integrated filling and sealing systems maximize production value by combining multiple processes (dosing, filling, tamping, sealing) in one continuous operation. These all-in-one solutions reduce floor space requirements by 40-60%, minimize product handling, and decrease oxygen exposure that can compromise coffee freshness.

I've helped several medium-sized roasters transition from modular systems to integrated lines, and the benefits extend beyond simple efficiency gains. These comprehensive systems create a controlled environment throughout the entire production process.

Benefits of Integration in Coffee Capsule Production

| Aspect | Separate Systems | Integrated Systems |

|---|---|---|

| Floor Space | 15-25 m² | 8-12 m² |

| Transfer Points | 3-5 | 0-1 |

| Oxygen Exposure | Moderate to High | Minimal |

| Contamination Risk | Higher | Lower |

| Production Monitoring | Multiple systems | Single interface |

| Maintenance | Multiple service schedules | Simplified maintenance |

Modern integrated systems are designed with hygiene in mind, featuring stainless steel construction and easy-access cleaning points. This becomes especially important when producing different coffee varieties, as thorough cleaning between batches prevents cross-contamination of flavors.

The control systems in integrated machines provide comprehensive production data, allowing operators to monitor performance metrics in real-time. This data-driven approach enables continuous improvement in production efficiency. For example, one client used their system's analytics to identify optimal dosing parameters that reduced coffee waste by 3.2% while maintaining perfect fill levels.

Conclusion

Investing in a quality coffee capsule filling sealing machine is essential for commercial success in today's competitive market. The right equipment delivers efficiency, consistency, and scalability while protecting your product quality and brand reputation.