Choosing between Nespresso and Dolce Gusto can be tough. The wrong choice means costly mistakes. I'll guide you through the key differences to make your decision easier.

The choice depends on your target market. Nespresso is for pure espresso lovers, offering simplicity and wide compatibility. Dolce Gusto targets variety, with larger capsules for milk drinks, teas, and more. Your product dictates the capsule, and the capsule dictates the machine.

I've seen many clients struggle with this exact decision. It's not just about the coffee; it's about the entire manufacturing ecosystem. To really understand which path is for you, we need to look closer at each system. Let's start with the most popular one.

First, what exactly is a Nespresso capsule?

You know the Nespresso brand, but what are its core features for manufacturing? It’s a precise system, not just a pod. Let’s look at the essential details.

Nespresso is a coffee capsule system invented by Eric Favre in 1986. It uses small, sealed aluminum or plastic capsules, typically 37mm in diameter, holding 5-6 grams of coffee. It's designed primarily for high-pressure extraction to produce espresso and lungo style coffees.

Nespresso started as an innovative, patented system, which meant for years, you could only buy official capsules for official machines. I remember when the patent expired. It was a complete game-changer for the industry. Suddenly, smaller roasters and entrepreneurs could enter the market. We started getting calls from all over the world from people who wanted to make their own "compatible" capsules. This boom showed me how a single design standard can create an entire ecosystem of opportunity. From a design and manufacturing perspective, the Nespresso capsule is a marvel of efficiency.

The Nespresso Standard

The Nespresso system is built around one core idea: delivering a perfect, consistent shot of Italian-style espresso. This requires high pressure, typically around 19 BAR, to force hot water through the finely ground coffee[^2]. This process creates the rich crema that espresso lovers value. The capsule is designed specifically for this. Its small size is not an accident; it's engineered to hold the exact amount of coffee for a single serving while withstanding the intense pressure during brewing. The quality of the coffee grind is absolutely critical. If the coffee granules are not uniform in size, the water will not extract the flavor evenly, resulting in a poor-quality shot[^3].

Target Products and Market

The primary product for Nespresso capsules is, of course, coffee. Specifically, espresso and its longer-shot cousin, the lungo. However, the format is also excellent for other fine powders that benefit from high-pressure extraction or quick infusion. I have helped clients successfully package high-grade matcha, fine leaf teas, and other specialty powders in Nespresso-compatible capsules. The target market is typically the coffee purist, someone who values the authentic taste and convenience of a quality espresso shot at the touch of a button. They appreciate simplicity and consistency over a wide variety of drink types.

Material and Design Considerations

From a production standpoint, the materials and design are straightforward. Most compatible capsules are made from either food-grade PP plastic or aluminum. Aluminum is often preferred as it's infinitely recyclable and provides a superior oxygen barrier, keeping the coffee fresh for longer.

Here is a simple breakdown of the Nespresso capsule's specifications:

| Feature | Specification | Notes |

|---|---|---|

| Diameter | 37 mm | A consistent industry standard. |

| Height | 30 mm | Standard size for original line machines. |

| Capacity | 5-6 grams | Ideal for single-shot espresso. |

| Material | Bio-degradable, Plastic (PP), Aluminum | Aluminum offers a better barrier. |

| Lid | Aluminum Foil | Heat-sealed to the capsule body. |

| System | High-Pressure (19 BAR) | Focused on espresso extraction. |

Understanding these details is the first step in designing a production line for this incredibly popular capsule.

And what about Dolce Gusto?

Dolce Gusto seems more complex than Nespresso. Its variety can be overwhelming for producers. Let's break down its system to see the opportunities it offers.

Dolce Gusto, also from Nestlé, is a versatile beverage system launched in 2006. Its larger, 54mm capsules hold 8-20g and can contain milk powders, chocolate, and tea, not just coffee. It supports both hot and cold brewing, targeting creative, multi-layered drinks.

If Nespresso is about perfecting one thing, Dolce Gusto is about offering everything. It was developed by Nestlé to bring the full "coffee shop experience" into the home. This means not just black coffee, but lattes, cappuccinos, hot chocolate, iced teas, and more. This versatility is its greatest strength and presents a unique opportunity for creative product developers. A client from Southeast Asia came to us a few years ago. They wanted to tap into the milk tea craze but in a single-serve format. The Nespresso capsule was too small. Dolce Gusto was the perfect solution. Its large capsule size could easily accommodate the milk tea powder, and the system could handle the preparation. We helped them design their filling line, and their product was a huge success. It proved to me that Dolce Gusto isn't just for coffee; it's a platform for beverage innovation.

The All-in-One Beverage System

The key to Dolce Gusto's versatility is its larger capsule and smarter machine. The system is designed to handle different ingredients, pressures, and even temperatures. Many Dolce Gusto machines can produce cold drinks as well as hot ones, which is a major advantage. It achieves this by being a more intelligent system. The machine often adjusts the brewing cycle based on the type of capsule inserted, delivering the right amount of water and pressure for anything from a short espresso to a long, frothy latte.

Target Products and Market

This system is designed for a much broader range of products. The large capacity is the most important factor here.

- Fancy Coffees: For drinks like a latte, you often need two capsules: one with espresso and one with milk powder.

- Milk Teas: As with my client's story, it's perfect for instant tea and milk powder mixes.

- Hot Chocolate / Cocoa: The capsule can easily hold a generous serving of cocoa powder.

- Instant Soups: I've even seen some innovative uses like single-serve soup broths.

The target market is very different from Nespresso. It appeals to families, younger consumers, and anyone who enjoys variety and likes to experiment with different drinks.

The "Smart Capsule" Design

The capsule itself is more complex. It's larger and has a unique design to handle different types of contents.

| Feature | Specification | Notes |

|---|---|---|

| Diameter | 54 mm | Significantly larger than Nespresso. |

| Height | 35 mm | Taller to accommodate more product. |

| Capacity | 8-20 grams | Allows for milk powders and other ingredients. |

| Material | Mostly Plastic (PP/EVOH/PP) | Multi-layered for a good oxygen barrier. |

| Lid | Aluminum Foil | Seals the capsule. |

| System | Variable Pressure, Hot & Cold | Designed for a wide range of beverages. |

This larger, more complex design directly impacts the type of machinery you need to handle and fill it, which is where things get interesting for a designer like you.

So what are the key differences for a manufacturer?

Knowing the basics isn't enough. The small differences have a big impact on your factory floor, your budget, and the quality of your final product. Let's compare the critical manufacturing details.

The main differences are capsule size and capacity, internal capsule structure, and the range of products you can make. Nespresso is a smaller, simpler capsule for espresso. Dolce Gusto is larger, more complex internally, and built for a wide variety of multi-ingredient beverages.

As a machine designer and manufacturer, I look at these capsules and see two completely different engineering challenges. The consumer sees a simple pod, but we have to think about everything from how the empty cup is fed into a machine to how it's sealed. These differences are not trivial; they define the entire production process. Let's break down the three most critical distinctions that you, as a designer, need to understand.

Difference 1: Physical Dimensions and Capacity

This is the most obvious difference, but its implications are huge. The Nespresso capsule's 37mm diameter and 5-6 gram capacity limit it to concentrated products. The Dolce Gusto's 54mm diameter and massive 8-20 gram capacity open up a world of possibilities. This size difference affects everything. It changes the cost of raw materials for each capsule, the size of the packaging, the shipping logistics, and most importantly, the design of every single component on the filling machine that comes into contact with the capsule. You cannot simply adjust a Nespresso machine to fit a Dolce Gusto capsule; the scale is fundamentally different.

Difference 2: Internal Capsule Structure

This is a more subtle but critically important difference. A standard Nespresso capsule is simple: it's a cup filled with coffee and sealed with a foil lid. A Dolce Gusto capsule, especially one for espresso, has an extra component. Inside, after the coffee is filled, we must place and seal a thin, plastic perforated film. This film sits between the coffee and the final foil lid. Its job is to help distribute the water pressure evenly across the coffee grounds. Without it, the water would just tunnel through the center of the large pod, leading to a weak, under-extracted espresso. This extra layer adds a full step to the production process, requiring an additional station on the filling machine.

Difference 3: Product Application and Market

These physical and structural differences lead to a clear divergence in market strategy.

Here’s a head-to-head comparison that summarizes the key points for a producer:

| Feature | Nespresso | Dolce Gusto |

|---|---|---|

| Target Product | Pure Espresso, Lungo, Fine Teas | Multi-beverages (Coffee, Milk, Tea, Chocolate) |

| Target Consumer | Coffee Purists, Office Environments | Families, Younger Consumers, Variety-Seekers |

| Internal Complexity | Simple: Coffee + Lid | Complex: Coffee + Perforated Film + Lid |

| Key Selling Point | Authenticity, Simplicity, Speed | Variety, Creativity, All-in-One Solution |

Choosing one over the other is a strategic business decision that should be made before you ever start thinking about machinery.

How do these differences affect the filling machines?

Okay, the capsules are different. But how does this change the machine you need? These differences radically alter the equipment, its complexity, and its price. Let's explore why.

Equipment differs in three key areas: cup feeding, filling/sealing molds, and the number of sealing stations. Nespresso machines use simpler vertical cup droppers. Dolce Gusto machines need special unscramblers and often have two sealing stations, increasing their complexity and cost.

I'll never forget a consultation with a new company that was just starting. They bought a machine online that was advertised as a 'coffee capsule filler'. They assumed, quite reasonably, that it would work for the Dolce Gusto capsules they wanted to produce. When the machine arrived, it was a disaster. The capsules wouldn't feed into the machine correctly, the seals were sloppy, and there was no way to add the internal perforated film. They had to scrap the entire machine and start over. It was an expensive lesson that I try to help all my clients avoid: the machine must be designed specifically for the capsule. Let's look at the three main functions that change.

Function 1: Empty Capsule Feeding

This is the very first step in the process and already we see a major difference.

- Nespresso: Nespresso capsules, especially the aluminum ones, are rigid and have a shape that allows them to be stacked perfectly. This means we can use a very simple and reliable vertical cup dropper. The machine just drops one cup at a time from the bottom of the stack into the mold. It's efficient and cost-effective.

- Dolce Gusto: Dolce Gusto capsules are plastic and have a shape that makes them impossible to stack neatly. You cannot use a simple dropper. Instead, you need a capsule unscrambler. This is typically a large vibrating or centrifugal bowl that tumbles the capsules around until they are fed, one by one, in the correct orientation, into the machine. This is a much larger, more complex, and more expensive module.

Function 2: Tooling and Molds

This is the heart of the machine. The capsules travel through the machine in a mold plate that has custom-fit pockets. Because the diameters are so different (37mm vs. 54mm), the entire tooling set must be different. This includes:

- The main mold plate that transports the cups.

- The filling head nozzles that dispense the powder.

- The tamping and cleaning station.

- The sealing heads that press the lids onto the cups.

- The cutting tools that trim the foil.

Every single one of these components is custom-engineered to the exact dimensions of the capsule.

Function 3: Sealing Stations

This is the final key difference.

- Nespresso: The process is straightforward. Fill with coffee -> Place a foil lid -> Heat seal the lid. This requires one sealing station.

- Dolce Gusto: For espresso, the process is more involved. Fill with coffee -> Place the internal perforated film -> Seal Station #1 -> Place the top foil lid -> Seal Station #2. This requirement for two separate sealing stations makes the machine physically longer, more complex mechanically, and increases the overall cost.

These three factors are why a Dolce Gusto filling machine is inherently a more significant investment than a Nespresso machine of a similar output speed.

Can one machine produce both Nespresso and Dolce Gusto capsules?

Buying two full production lines is a huge investment in money and space. You might feel forced to choose just one capsule type. But there is a smarter way.

Yes, universal machines exist. At AFPAK, we design machines with interchangeable molds. This allows you to produce both Nespresso and Dolce Gusto capsules on a single machine by swapping out the tooling set, saving significant space and initial investment. The changeover is quick and straightforward.

We developed this concept because I saw so many of my clients starting small. They were excited about the single-serve market but weren't sure which capsule would be a winner for them. They wanted to test both Nespresso and Dolce Gusto products without having to double their initial machinery costs. This is a very common problem, and for years, the only answer was to buy two machines. We decided to create a better solution. This thinking is the core of our slogan: "Intelligent your production". It's about finding smart, flexible ways to help our clients succeed.

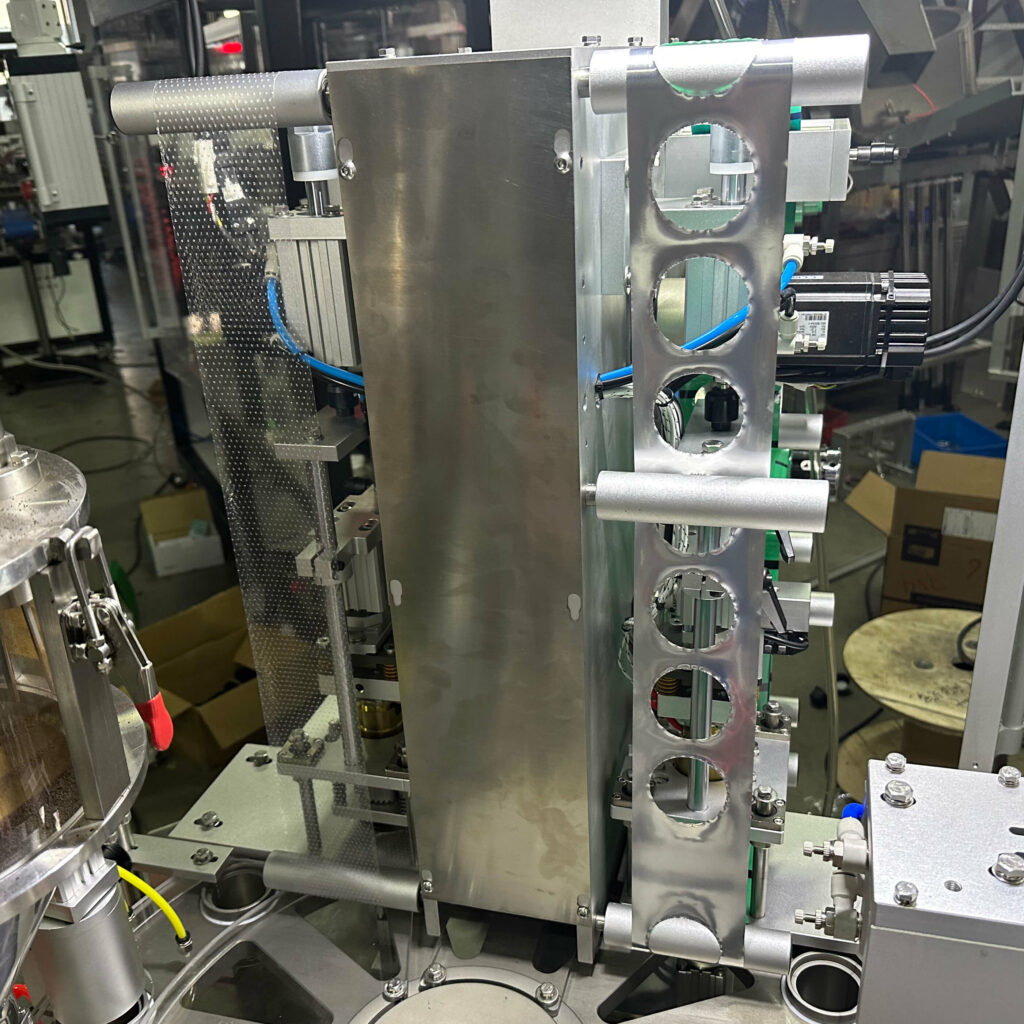

The Power of Interchangeable Molds: only 30 mins to make changeover

The solution is to build a machine on a common platform but design the parts that touch the capsule to be completely removable and swappable. Think of it like a "cassette" system. You have one base machine that contains the main motor, the control panel, and all the electronics. Then you have a complete mold set for Nespresso and another complete mold set for Dolce Gusto. This set includes the mold plate, the filling head, the sealing heads, everything. To change from one capsule to another, you simply unbolt one set and install the other. This modular design is the key to flexibility.

Solutions for Startups and Small Batches

For entrepreneurs, small coffee roasters, or companies looking to test the market, this is a perfect solution. We designed our AFPAK RN1S model specifically for this purpose. It's a compact, reliable rotary machine that can be equipped with interchangeable molds. One of the best features is that the changeover is fast. A trained operator can switch from producing Nespresso to Dolce Gusto in about 30 minutes. This means you can run a batch of espresso pods in the morning and a batch of hot chocolate pods in the afternoon, all on the same machine. It drastically lowers the barrier to entry and allows for incredible agility in your product offerings.

Scaling Up with High-Speed Flexible Lines

This flexibility isn't just for small machines. As our clients grow, they need more speed and automation. Our larger linear machines, like the AFPAK RN180 or H4 models, are also designed with this same principle of interchangeable molds. These are high-speed, multi-lane machines that can produce hundreds of capsules per minute. They maintain the ability to switch between capsule types, giving large-scale producers the ability to adapt to changing market demands without needing a whole new production line. These machines can also be easily integrated with downstream equipment, like our automatic cartoning machines, to create a fully automated line from empty capsule to shelf-ready box. It provides a clear growth path for our clients, from their first test batch to full-scale production.

RN1S Dolce Gusto Filling machine working video

RN1S Nespresso Filling machine working video

Conclusion

Choosing between Nespresso and Dolce Gusto depends on your product goals. Understanding their key differences in design and production machinery is the first step to a successful launch.