Automated Testing Systems

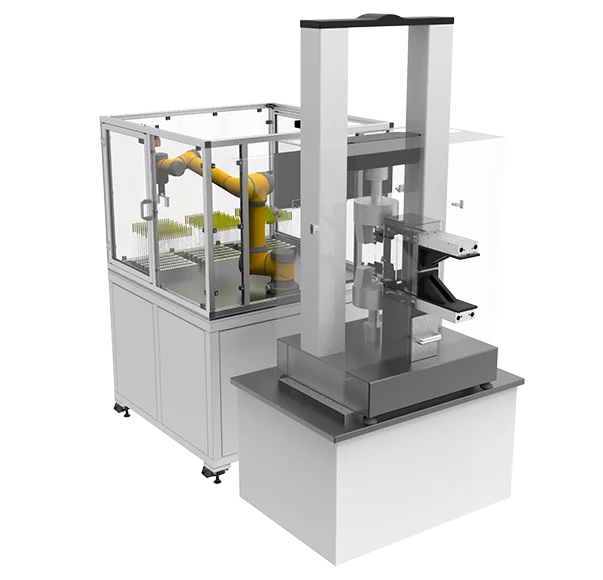

Yantai Dreaming Instrument Equipment Co., Ltd. independently developed fully automatic universal material testing system can achieve fully automated material testing process, including sample gripping, dimensional measurement, material testing, waste sample collection, test report generation, etc.,

the system is compatible with INSTRON, ZWICK, SHIMADZU and other brands of universal material testing machine, the main body of the three-axis servo system or six-axis robot design.

Compact structure, small footprint, can ensure large volume and high precision repeatability test, the number of sample storage can be expanded to 300

Suitable for rigid plastics, elastomers, film, foam, metal sheet, wire and other materials for tensile, tearing, bending and compression and other materials to carry out the full automation of the test process.

It has the advantages of high safety, excellent ergonomics, reduced operating costs, improved accuracy of test results, elimination of human error and intelligent analysis of data.

Fully automatic universal material testing system

The Automated testing system can realize fully automated material testing process, including sample gripping, dimensional measurement, material testing, waste sample collection, test report generation, intelligent analysis of experimental data, etc. This system is compatible with INSTRON/ZWICK/SHIMADAZU and other high-end brands of universal material testing machines, and the host computer adopts three-axis servo system or six-axis robot design, which has a compact structure, a small footprint, and ensures High-volume and high-precision repeatability of the test, the number of sample storage can be expanded to 300, suitable for rigid plastics, elastomers, film, foam, metal sheet, wire and other materials for tensile, tearing, bending and compression and other test process of full automation. It has the advantages of high safety, improved ergonomics, reduced operating costs, improved accuracy of test results, elimination of human error, intelligent analysis of test results, etc.

Automated Testing System

Fully automated

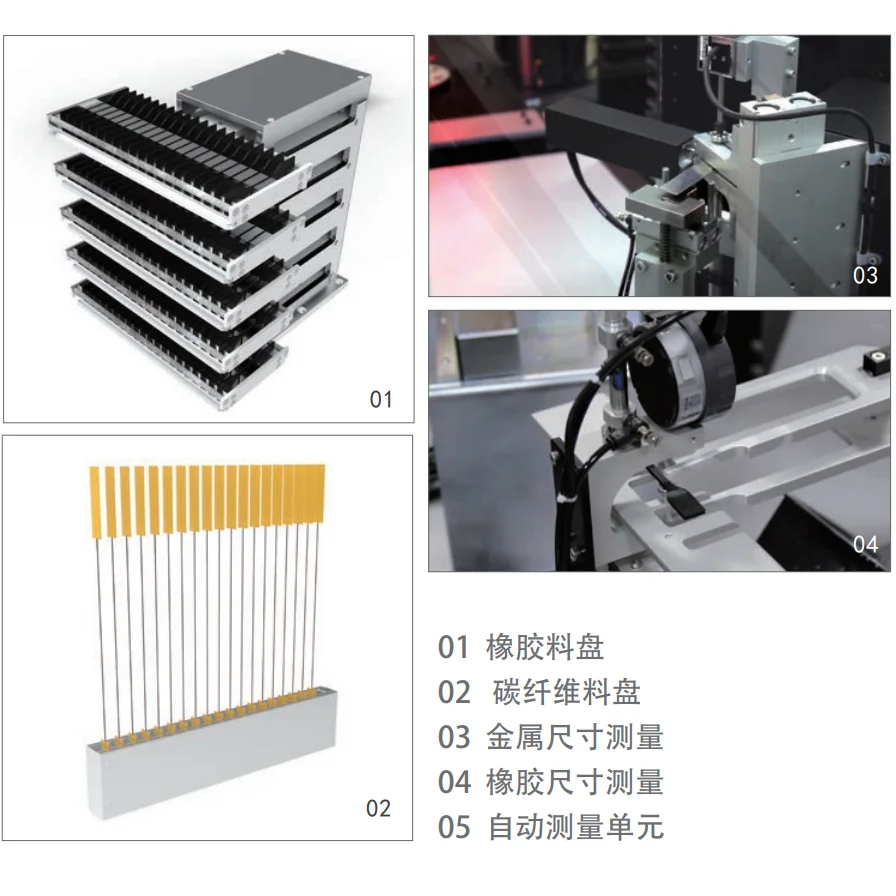

6-axis robotic elastomer material testing systemRobot Test-R 6-axis robotic fully automated elastomer material testing system is designed with a 6-axis robot for fully automated elastomer tensile and tear tests (e.g. according to GBT 528, ISO 23529).

It has the advantages of small footprint, high safety, excellent ergonomics, reduced operating costs, improved accuracy of test results, elimination of human error, and intelligent analysis of data.1Industry

Elastomer /Soft Material2Type of test

Tensile | Tear | Compression3Test range

Lightweight | Large quantities3Test standard

GBT 528, GBT 529, GBT 2941, ISO 23529, ISO 37 ISO 34

6-axis robotic fully automated plastic material testing system

The Robot Test-P 6-axis robotic fully automated plastic material testing system is designed with a 6-axis robot for fully automated plastic tensile and flexural testing (e.g. according to ISO 527-2, ISO 178 or ASTM D638).

It has the advantages of small footprint, high safety, excellent ergonomics, reduced operating costs, improved accuracy of test results, elimination of human error, and intelligent analysis of data.1Industry

Plastic2Type of test

Stretching | Bending3Test range

Lightweight | Large quantities3Test standard

ISO 16012, ISO 527, ISO 3167, GBT 9341, GBT 1040

3-axis servo-electric cylinder type fully automatic elastomer material experiment system

Servo Test-R 3-axis servo-electric cylinder type fully automatic rubber material test system adopts innovative 3-axis robotic arm design for fully automatic rubber tensile and tear tests (e.g. according to GBT 528, ISO 23529).

It has the advantages of small footprint, high safety, excellent ergonomics, reduced operating costs, improved accuracy of test results, elimination of human error, and intelligent analysis of data.1Industry

Elastomer /Soft Material2Type of test

Tensile | Tear | Compression3Test range

Lightweight | Large quantities3Test standard

GBT 528, GBT 529, GBT 2941, ISO 23529, ISO 37 ISO 34

Fully automated 6-axis robotic fibre material testing system

The Robot Test-F 6-axis robotic fully automated fibre material testing system is designed with a 6-axis robot for fully automated fibre tensile testing (e.g. according to ).

It has the advantages of small footprint, high safety, excellent ergonomics, reduced operating costs, improved accuracy of test results, elimination of human error and intelligent data analysis.1Industry

Fiber2Type of test

stretching3Test range

Lightweight | Large quantities3Test standard

GBT 528, GBT 529, GBT 2941, ISO 23529, ISO 37 ISO 34

Applications of Automated Testing System

Fully automated universal material testing system can realize the full automation of tensile, tearing, bending, compression and other tests, which can provide high safety and high efficiency automated testing for different materials and different sizes. Soft materials: films, textiles, fibers, high elastomers, etc. Hard materials: metals, plastics, composites, etc.

Advantages 1: Safety

Product accidents or physical injuries can have a huge impact on a company.

Automation equipment can minimize repetitive movements of personnel and eliminate human-computer interaction processes, thus fundamentally avoiding the potential for operators to cause physical Shanghai, saving the company valuable time and money.

Ξ The products are equipped with safety interlocks, emergency stop buttons and safety guards, which can realize the emergency braking of the equipment under non-safety conditions.

Ξ Eliminate human-machine interaction. The operator is far away from the test area, which fundamentally avoids physical injury to the operator.

Advantages 2: Ergonomics

Eliminates repetitive movements of manual testing and avoids fatigue injuries, such as sample loading, dimensional measurements, removal of broken parts, etc.

02 Satefy protection

03 Safety Lock

04 One button to stop the machine

Advantages 3: reduce costs

1. Reduce training costs

Well-trained operators are essential to ensure the integrity and accuracy of experimental results. When there is a turnover of skilled operators, companies need to spend a lot of money and time to train new operators, and at the same time, production time is also affected by the training of new employees, automatic universal materials testing machine is designed to use the minimum training to obtain the most reliable and accurate test results!

2. Unattended operation can be realized

The total number of samples of the fully automatic universal material testing machine can be expanded to 300, with unattended testing capability at night, the laboratory does not need to add additional shifts to realize 24 hours of gapless work.

Advantages 3: reduce costs

Create a free account with us to design a sample website.

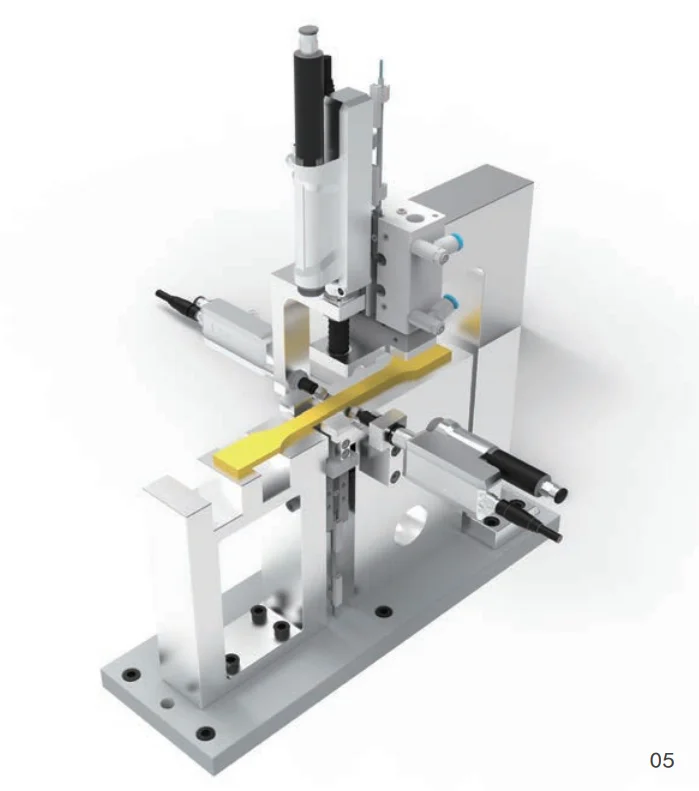

Advantages 4: Improve test accuracy and repeatability

Human factors can easily affect data accuracy and repeatability

Measurement of sample dimensions

Sample attitude when clamped in a tensile tester

Operator skills

Process errors such as incorrect manual input of dimensions, incorrect manual clamping sequence of samples, etc.

Repeatability and reproducibility studies of the GR&R system have shown that when the test process is fully automated, the influence of human factors on the results is zero.