Many users always encounter a problem when they first get the AFPAK k cup filling and sealing machine to try to produce, that is, the phenomenon of spreading powder is very serious, resulting in unattractive coffee capsules. This article will analyze in detail the causes and solutions of powder spreading

How does coffee fill into cups?

First of all, to understand the reason for spreading powder, we have to be familiar with the operation logic of powder filling.

The coffee or other powder is rotated inside the filling hopper by the screw/auger, and the powder stored on the screw/auger will flow to the inside of the cup, (this set of mechanisms is not suitable for powder with too good flowability). There is usually a stopper at the lower nozzle to prevent the powder from spreading. And the screw/auger is controlled by a high precision servo motor, and the number of turns of servo rotation to control the amount of powder filling.

Why the coffee will spread out?

Usually, the spreading of powder generated by factors such as wrong parameter settings, cup position is not adjusted correctly, and the powder in the flow of static electricity and other reasons. Next, we will check one by one

1- Cup position:

This is a relatively common situation. Because the hopper needs to be cleaned frequently, it is inevitable that the position deviation will occur during disassembly, so in the case of spreading powder, the position needs to be lined up:.

- whether the hopper is pushed into place: In the process of cleaning, we will lift the hopper position, as well as move out to clean, so in the process of putting back need to pay attention to whether the hopper has been pushed back to the cup-centered position?

- In addition, we also need to check whether the cup has completely touched the material nozzle after the top-up, with no gaps? If there is a gap, the powder will spill through the gap to the outside

In short, the filling process is to ensure that: the cup is facing the filling spout and that the filling spout completely covers the mouth of the cup without gaps, so that the coffee powder will not spill

2- Parameter settings:

After the position are right, if there is still a spreading powder situation, there is a need to check whether the parameter settings are reasonable

The filling parameter setting is made up of two parts: the filling time, and the servo parameters. The two sets of parameters work well with each other to achieve perfect filling

2.1- Filling time:

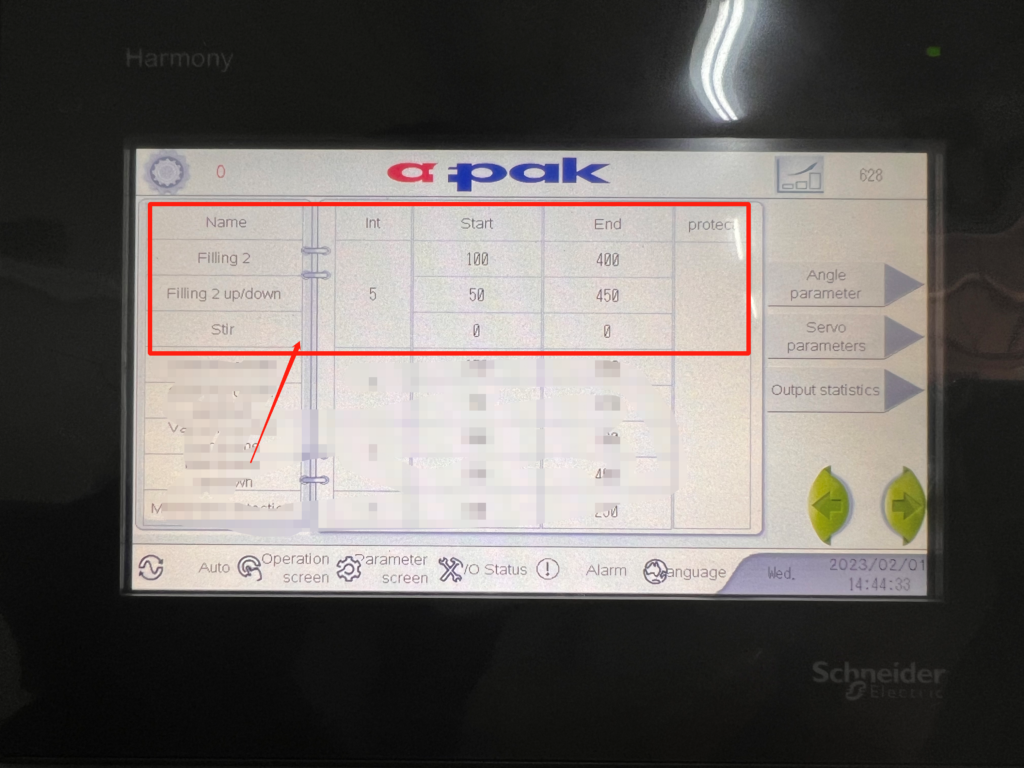

mainly consists of three parameters: Filling/ Filling UP/Down/blender

The filling is to control the time from the beginning to the end of the coffee powder filling, generally set between 950-450

Filling UP/Down is to control the time when the cup starts to come up and drops back to its original position. Generally set between 950-450

Stir is the time to stir the coffee powder in the hopper, which can be ignored.

Note that the above angle parameter settings are based on the value on the machine’s encoder, which represents the current machine stop position. Can not be set and changed at will

Generally, after the cup reaches the lower spout, the coffee powder starts to fill, then after the filling is finished, the cup returns to its original position.

2.2- Servo Parameters:

When you click on the servo parameters on the left side of the screen, you will see the above page

There are six parameters on this page: Fill weight, Fill Ratio, Fill Servo speed, Clearing speed, Servo acceleration, and servo deceleration.

Fill weight and Fill Ratio is to set the filling weight parameters. you can check this video to learn how to set these two parameters:

Fill Servo Speed is to adjust servo motor turning speed, normally for K cups, we set 1500-2500, and for Nespresso, we set 1000-1500.

Servo acceleration is to set the parameters to start the auger turning, which means how fast the auger can reach the fastest turning speed, normally set 50-300

Servo deceleration is to set the parameter to stop the auger from turning, which means how fast the auger can stop turning, normally set 50-300

3- Static problem:

We found that the darker the coffee is roasted and the richer the oil is, the more likely it is to generate static electricity during the filling process.

After the generation of static electricity, the coffee powder is more likely to stick to the downstream spout, making the coffee powder transfer to the cup and other parts of the cup during contact with the cup.

Therefore, it is best to configure some electrostatic elimination devices to prevent this type of situation from occurring.

Specific methods of eliminating static electricity can be answered by contacting our sales engineers, who have summarized a set of static electricity elimination solutions based on customer feedback, which substantially helps customers solve many problems of spreading powder.

The above is our summary of the causes and solutions to the problem of spreading powder, there may be other situations that lead to the occurrence of such problems, we welcome feedback from our readers, and we sincerely welcome more comments and suggestions

About the Author

Jeffree Fang – Owner of AFPAK

As one of the first technicians in China to research coffee capsule filling and packaging technology, with more than ten years of front-line sales, design, R&D, and production experience, he has helped hundreds of coffee companies to set up their coffee capsule production lines successfully so far. He has been committed to developing higher-end, more advanced coffee capsule filling and packaging machines and constantly collecting feedback from customers, making AFPAK’s machines more and more popular.