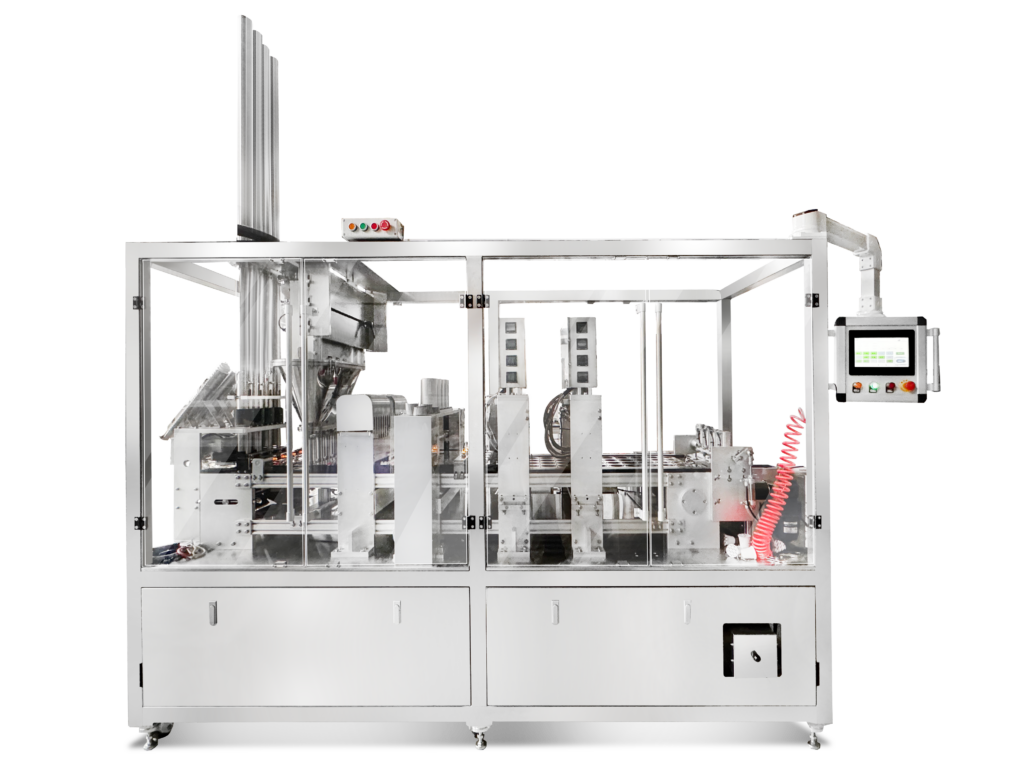

AFPAK’s H series K cup filling packaging machine is ideal for k-cups filling, sealing, nitrogen flushing, and cartoning production. This machine can pack coffee granules, soluble powders, tea granules/leaves, cocoa powders, etc with simple changes. This equipment is feature-rich, occupies a small area, stable performance and excellent quality. Now we have 2/4/6/8 lanes machines for you to choose, each lane can produce 40-50 cups per minute.

Functions

This machine has all functions to produce quality k-cups

1- Empty k cups feeding

2- No cups no filling sensor

3- Servo filling with auto coffee feeding system

4- Cup rim cleaning system

5- Pick and place pre cut lids (also can use roll film)

6- No lids no sealing sensor

7- Twice sealing system

8- Output to conveyor

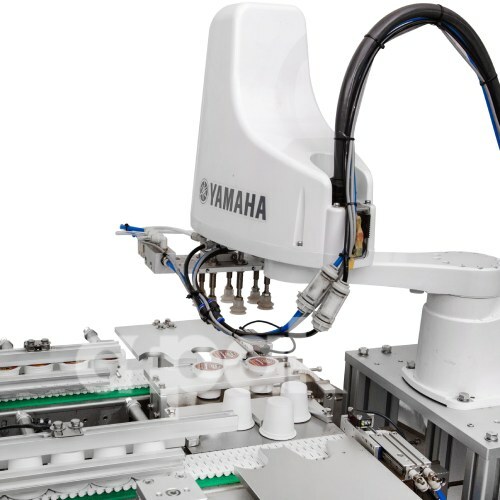

9- Robot hand to pick 2*3 k cups

10- Open the empty boxes

11- Insert K cups into the boxes

12- Spray glue for seal

13- Seal the boxes

14- Output the final boxes

We also have many options

O1: Inline weight scale

O2: Date printer

O3: Second capsules production kits

O4: Inline camera to check sealing quality

O5: Flavor doser

O6: Ionizer

O7: We can also add other functions as you want

Benefits:

1- One person is enough to run this system

2- One machine can fill different products

3- One machine can use different sealing materials

4- One machine can pack different sizes of boxes

There are many more benefits are waiting for you to explore

Details:

| Model | HB210 | HB410 |

| Working lanes | 2 | 4 |

| Type | Linear type | |

| Capsule feed | Vertical | |

| Drive Type | Motor drive, 220v single phase / 60Hz / 50amps | Motor drive, 220-380v three phases / 60Hz / 60amps |

| Output | 80-100 cups p/min; 6000 p/hr | 160-200 cups per minute 1200 cups per hour |

| Filling accuracy | +/- 0.2 grams | |

| Machine weight | 3300 lbs | 4000 lbs |

| Dimensions | 196″x95″x100″ (LxWxH) | 196″x110″x100″ (LxWxH) |

| Power Consumption | 3.5 Kw/h | 5.5Kw/h |

| Nitrogen Consumption | 50-100L/min 0.1 Mpa | 100-300L/min 0.1MPa |

| Air Pressure Consumption | 100-200L/min 0.6-0.8 Mpa | 300-400L/min 0.6-0.8Mpa |

| Warranty | 2 year mechanical, 1 year electrical | |

| Note | We also have 6/8 lanes for you to choose | |