What is the coffee can filling machine?

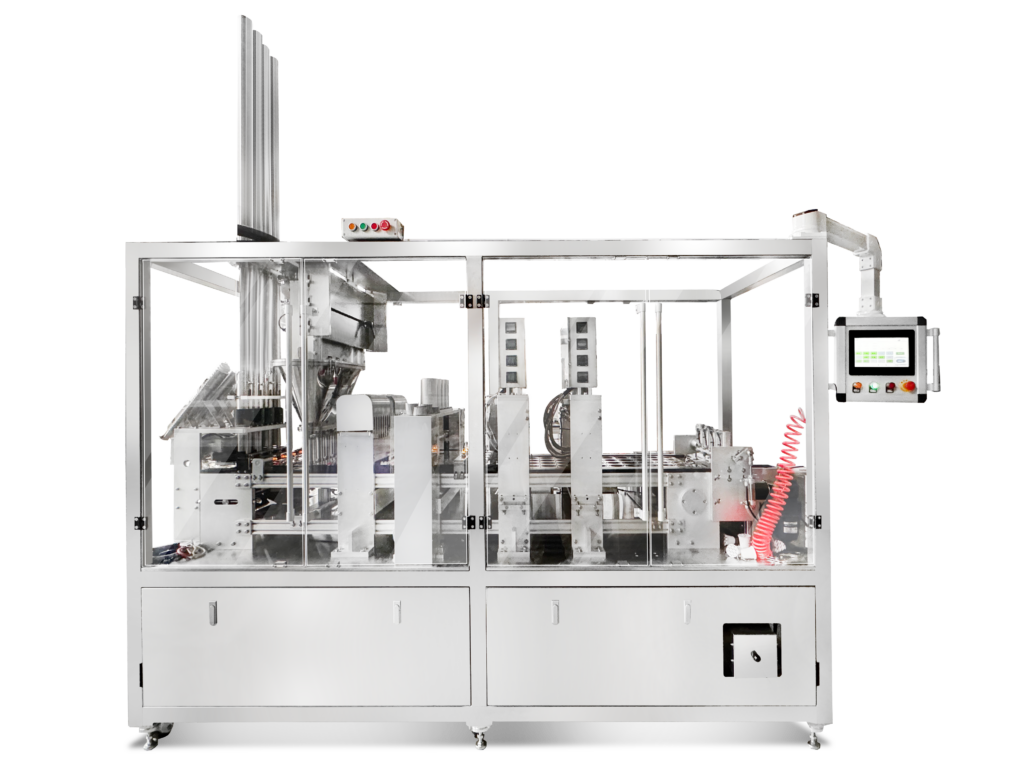

Coffee can filling machine is a fully automatic solution for filling and sealing coffee into cans or tins. The coffee tin/can filling machine produced by AFPAK is suitable for small and medium-sized enterprises, and is fully in line with food hygiene standards. It has a fully automatic operation, can be operated by one person without complicated maintenance. It can produce products of various specifications and excellent workmanship, use of high-quality electrical components, does not require a lot of space, etc.

The coffee can filling machine is widely applied, you can use it to produce liquid coffee, juice, oil, alcohol, and other products, and even use it to produce carbonated beverages. It can help you develop your beverage business quickly

This coffee can filling equipment is manufactured by our company based on years of accumulated experience and innovative design. It has a better design structure, updated technical foundation, more stable operation, more precise control, and other characteristics. Everything is to make you easier to use as the starting point, we have been working hard to create better equipment

Come and contact us to customize your exclusive equipment

AFPAK Coffee can filling machine specifications

| Model | AF-CFM100 |

| Machine speed | 1500-3000 cans per hour |

| Filling head | 12 heads (can customized according to your requirement) |

| Sealing head | 1 head (can customized according to your requirement) |

| Filling Range | 300-500 ml adjustable |

| Filling Method | Peristaltic pump |

| Filling speed | 20-40 cans/min |

| Filling accuracy | 1% -+ |

| Conveying speed | 5-15 m/min |

| Conveyor length | 2 m |

| Conveyor height | 850-900 mm |

| Power | 1500 W |

| Voltage | Single phase 220V, 50/60HZ |

| Control | PLC +HMI |

| Air source | 0.5-0.8MPa |

AF-CFM100 Coffee can filling machine function:

- Auto feed the empty cans

- Auto flip over and wash the cans

- Auto Filling drinks

- Auto filling liquid nitrogen

- Auto place the lids

- Auto sealing the lids

- Auto dry the cans

- Auto print date

- Auto Output

AF-CFM100 Coffee can filling machine features:

- Suitable for various liquids with good fluidity, such as pure juice, brake fluid, etc.

- Filling volume parameter adjustment control, very precise and precise

- The filling head can be customized according to the customer’s output requirements

- Start the turntable only when there is a tank; the speed of the turntable can be adjusted separately; when a tank jam occurs, the turntable will automatically stop, and the fault can be removed after one-button reset to run again; when a foreign object jams the turntable, the turntable will automatically stop running to prevent man-made Equipment damage and safety accidents caused by the wrong operation of equipment.

- A total of 4 two sealing rolls complete the sealing at the same time to ensure a high degree of sealing.

- The tank body does not rotate during the sealing process, which is safer, especially suitable for fragile and liquid products.

- The sealing speed is fixed at 33 cans per minute, and automatic production can improve production efficiency and save labor costs.

Detailed pictures

AFPAK – Professional can filling machine manufacturer from China

As a professional beverage machinery manufacturer, SHANGHAI AFPAK CO., LTD has more than 10 years of design experience and a number of proprietary technologies.

In addition to being sold to provinces, cities and districts, the products have also been exported to more than 30 countries including the United Kingdom, Canada, France, Russia, Malaysia, Vietnam, and Nigeria.

The international market is very broad, and the export volume is increasing year by year.

Our factory integrates advanced manufacturing technology at home and abroad and rich experience in whole plant design.

From project actions to later executions, a professional team can provide you with high-quality and efficient services.

Technology is the source of innovation, and innovation is the driving force for development.

Our company adheres to the business philosophy of “people-oriented, quality-based, honesty as a virtue, and excellence”, with a keen market sense and broad spirit of cooperation, to provide you with the strong technical guarantee and comprehensive support for producing perfect products.

Our factory is located in Jinfeng Town, Zhangjiagang City, in the prosperous Yangtze River Delta.

It is adjacent to the international metropolis Shanghai in the east and Nanjing, the ancient capital in the west.

Water and land transportation is extremely convenient.

Warmly welcome friends from home and abroad to visit our company to visit and guide, and to discuss cooperation. AFPAK is willing to sincerely cooperate with you and seek common development!

Coffee Can Filling Machine: The Ultimate FAQ Guide

Choosing a high-performance coffee can filling machine can be an overwhelming task without the right information.

That’s why this guide covers all the vital aspects of this coffee can filling equipment – from features, working principle, uses, benefits to specification, among other vital aspects.

So, if you want to be an expert in coffee can filling machine, read this guide.

Why Invest in Coffee Can Filling Machine?

Coffee can filling machine is a solution used to pack liquid coffee into the cans which is the most popular package format in the market.

For instance, it makes the packaging of liquid coffee simpler and faster thus saving on time and tediousness of human labor.

This machine is also easy to use because it is automatic.

Investing in this coffee can filling machine is beneficial because it can easily be maintained.

This guarantees its use for a long time without incurring additional expenses, thus yielding high returns.

I would also encourage you to invest in this coffee can filling device because it can be used in packaging many other products.

In addition to these, this machine ensures the coffee taste is not compromised to either air or light during packaging.

What is the Function of the Coffee Packer Machine?

This equipment is relevant in performing many functions.

Below are some of its functions:

- This Coffee can filling machine has a large cans storage platform, so you can put more than 1000 cans on it. Save lots of your time

- These devices help in washing the packaging materials to make sure their texture is fine.

- The machine can mix carbon-oxygen into the drinks before filling, so you can make the carbonated drinks also.

- This machine has a newly developed lids sealing system, the sealing process will be more smooth and provide beautiful sealing results.

- Apart from these, it can be used to package other liquid products like juice, beverages, oils, and medicines.

- Lastly, this machine can have many optional functions as you want. It is a fully customized solution

What standard functions do the AFPAK CFM100 coffee can filling machine include?

1- empty cans sorter and feeding table

The mechanism is composed of a conveyor belt and a stainless steel structure, which can store up to 1000 cans, which effectively saves time.

- 1.2m*1.6m wide

- The frame is made of stainless steel material

- Feeding Speed is adjustable

- Can load more than 1000 cans

Can also be made in larger or smaller sizes

2- Cans flip over system

The structure is made of food-grade plastic materials and is designed according to your can, which can better protect the jar from damage or scratches

3- Cans washing machine

Can washing machine, can washing machine, for the cleaning of tinplate, aluminum cans and other cans, magnets are used to absorb the can body, so that the can can be turned over 180° along with the circular conveying, the mouth of the can is downward, and the pure water flows into the can by the pressure of the water pump. Water is flushed for cleaning, the cans continue to be conveyed and output along with the ring magnet, drained while being rinsed, and then conveyed to the next filling link.

Can washing machine specification:

| Model | XGJ5000 |

| Production | 2000-3000 cans per hour |

| suit for cans diameter | Φ40—Φ90mm |

| Motor Power | 0.75 kw |

| Out dimensions | 2380*600*900mm |

| Machine weight | 150 Kgs |

Can washing machine features:

1. High degree of automation, easy operation, stable operation, can effectively save enterprise costs and improve production efficiency.

2. Every single machine can complete its work independently, with the independent operating system, and electrical components such as numerical control display to control and adjust various parameters, and display settings. Can help companies achieve standardized production.

3. Every single machine is linked and separated quickly, and adjustment is quick and simple so that every process of production can be coordinated.

4. Every single machine can adapt to the packaging of various specifications of bottles, and there are few adjustment parts.

5. This packaging production line adopts international new technology design and conforms to GMP standards.

6. The production line runs smoothly, each function is easily combined, and maintenance is convenient. Various production combinations can be carried out according to the user’s respective product process requirements.

4- Negative pressure coffee can filling machine-12 heads

Main structure:

It is composed of the workbench, transmission parts (including speed-regulating motor, reduction box, wine tank), wine valve (automatic wine inlet valve), pull the wheel, tray, conveying system, etc.

Performance:

(1) This machine is equipped with a safe and controllable automatic filling system, and the liquid level in the bottle is controlled accurately.

(2) Beautiful appearance, compact structure, perfect control system, convenient operation, and a high degree of automation.

(3) The filling cylinder, filling valve, and material contact parts are made of micro-carbon stainless steel with a polished inner wall, which is corrosion-resistant and easy to clean.

(4) This machine adopts a speed-regulating motor, and the production capacity can be adjusted arbitrarily.

Filling machine specification

| Model | GZJ 2000 |

| Production | 1500-3000 cans per hour |

| Filling heads | 12 heads |

| Suit for cans | Dia:50-95 mm, Height: 80-290 mm |

| Motor Power | 0.75 kw |

| Out dimensions | 1000×800×2000mm |

| Machine weight | 450 Kgs |

5- Can sealing machine

The above can sealing machine is newly developed by our company according to customer requirements.

The equipment of this product has stable production performance and a high degree of automation, which is suitable for sealing production line equipment.

Features of automatic can sealing machine:

1. Transmission system: cover sorting device, speed regulating motor, main shaft, indexing plate, rotary head, plc single-chip microcomputer pneumatic components, etc.

2. Covering system: There are two kinds of metal cover and plastic cover.

(1) The metal cover is composed of a thread cutter pressure spring and gland head.

(2) The plastic cap is composed of a capping die and a capping head.

Can sealing machine specifications:

| Model | FKJ 1000 |

| Production | 1500-2500 cans per hour |

| Sealing heads | 1 head |

| Suit for cans | According to your cans |

| Motor Power | 0.75 kw |

| Out dimensions | 1150x900x1850mm |

| Machine weight | 650 Kgs |

6- Hot and cold tank 1t

①. Manufacture, pressure test, and acceptance according to “Technical Conditions for Steel Welded Vessels”.

②. The volume is 1000L and other specifications, and it can also be designed and processed according to the actual needs of customers.

③. The seal of the stirring shaft adopts an imported sanitary mechanical seal, and the reducer adopts the world-famous brand of Germany Flanders, and the stirring speed is 36-53 rpm. It can also be controlled by a frequency converter.

④. The container heat preservation material adopts high temperature resistant and anti-aging pearl cotton.

⑤. The interface adopts the international universal ISO standard quick-mounting chuck type, the inner tank is imported 316L or 304, the inner surface is mirror polished Ra0.28μm-0.45μm, and the outer surface is polished matt or imported 304 mirror panel.

⑥. The tank has a level gauge (non-contact ultrasonic, static pressure transmission type or glass tube type), thermometer (digital display type or dial type), universal tank washer, air-breathing apparatus, sight glass, manhole, Liquid inlet and outlet, and circulation system interface.

Tank Specifications:

| Storage capacity | 1 Ton |

| Interior material | 316L or 304 |

| Internal finish | 0.28~0.45μm |

| Appearance material | 304 mirror panel or matt panel |

| Sterilization pressure | 0.15~0.3Mpa or normal pressure |

| Out dimensions | 1150x900x1850mm |

| Working pressure | normal pressure |

Configuration:

◆Deceleration device

◆Folded microporous membrane air filter (filters ≥0.01μm bacteria)

◆Leak-proof device (up to 100%)

◆Level gauge interface (static pressure sensor type, ultrasonic, glass tube side position for selection)

◆ Thermometer and flow meter interface (temperature sensor, flow valve)

◆Exhaust and safety valve interface (connected to a respirator with sterile filter)

◆Steam sterilization filter sterile ventilation interface

◆Cleaning ball interface (360-degree rotation under low pressure)

◆Import and export of liquid medicine (quick loading type)

◆Manhole

7- CQ2-1500 Beverage Mixing Machine

Equipment overview:

CQ2-3000 beverage mixer is developed by our company by absorbing imported technology and combining the actual production of carbonated beverages.

It has the international advanced level and is in a leading position among similar domestic products.

This mixer is suitable for the mixing and processing of various carbonated beverages, and can also be used for the mixing and processing of other beverages such as slurry beverages and fermented beverages.

Features of this machine:

a. Excellent selection of materials and refined processing: All parts in contact with beverages (such as containers, pipes, etc.) are made of imported 304 high-quality low-carbon stainless steel, and the inner and outer surfaces are precision polished, which fully meets the requirements of international food hygiene standards.

b. Fully automatic, with alarm: The pressure and liquid level in each tank of this machine are automatically adjusted, and the whole process of production operation is controlled by a microcomputer (PLC).

In the event of a malfunction, there will be warning lights, alarm bells and automatic shutdown. And it adopts touch screen control, all action programs are displayed on the flow chart on the touch screen.

c. Easy to operate and easy to adjust: The machine is particularly convenient to operate.

As long as you turn the knob in sequence according to the prescribed procedure, you can achieve normal operation.

Without replacing any parts, you can easily adjust the production capacity, water, syrup ratio, Gas content and so on.

d. Uniform mixing and proportioning: due to the advanced technology of one-time mixing, the mixing is uniform.

The mixing ratio of water and syrup is strictly controlled by a fine-tuned metering needle valve, and its accuracy can reach about five thousandths.

Enough gas and high efficiency: This mixer adopts vacuum deoxidation at room temperature, and the deoxygenation rate is over 90%.

It is equipped with a plate heat exchanger to cool the sugar-water mixture for secondary carbonation, so the gas content is particularly high, up to 3.5- More than 4 times.

e. Self-cleaning and high cleanliness: This machine is equipped with an in-situ cleaning device, which can automatically clean and disinfect the interior of the mixer and filling machine without disassembling any parts (container-type pipes).

The beverages produced by this machine can be automatically cleaned and disinfected.

The proliferation rate of bacteria per milliliter is less than 5%, and E. coli is zero, which meets the requirements of international food hygiene standards.

F. The diaphragm pump is used for uniform mixing and stable operation.

CQ2-1500 Beverage Mixing Machine

| Mixing capacity | 1000 Kg/h |

| Mixing ratio range | 3:1~6:1 |

| CO2 content | 3.5~4.1* |

| Mixing accuracy | 0.05BVX |

| Air pressure | 0.6-1 MPa |

| CO2 Feeding Pressure | 0.8-1 MPa |

| Mixing temperature | <4℃ |

| Power | 6.5Kw |

| Dimensions | 1500×1000×2500mm |

| Weight | 800Kgs |

8- Automatic chiller

Industrial schematic diagram of chiller:

The machine provides an environment below 4 degrees for the mixer, which can effectively help the synthesis of CO2 and coffee and other beverages

What are the Quality Standards for Coffee Can Filling Machine

The quality standards for coffee can filling machines are many.

For example, it must be made in compliance with CGMP which is a good manufacturing practice.

The equipment must also be manufactured in compliance with CE, which supports its hygienic status.

This is very important because it’s used to package products that should guarantee human safety.

It must be made from materials that are free from corrosion like SUS304 stainless steel.

This is because they are easy to clean and maintain.

This machine must have a PLC with a touch screen where all its operations are pre-determined.

It’s this component that provides a platform where the results of the process are read for adjustment purposes.

Good coffee can filling machine should have the capacity to feed, wash, fill, seal, dry from the machine.

This will ensure a uniform quantity of coffee cans at the end of the packaging process.

Lastly, a good coffee can filler packaging machine should have sensors that detect the cans before filling.

This prevents wastage of products during the packaging process.

At AFPAK, we design and manufacture high-quality and reliable coffee can filling packaging machines.