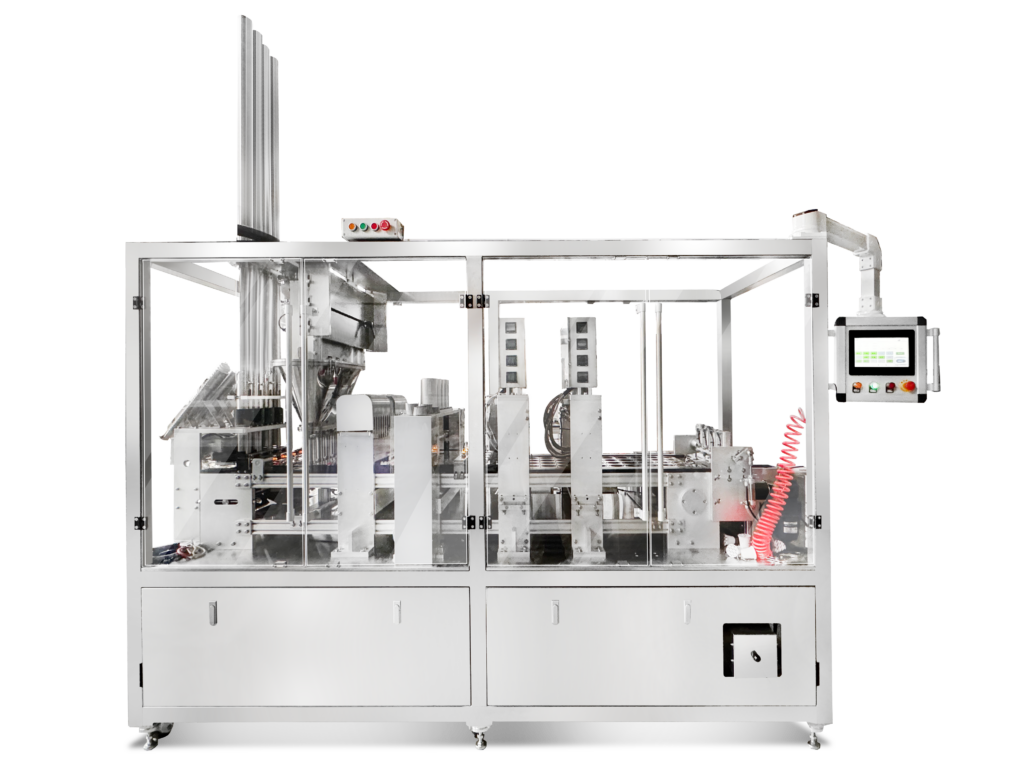

AF-H1 dolce gusto filling closing machine is the solution to fill coffee in Dolce Gusto capsules, close and pack with Nitrogen gas.

This is a full automatic line with incorporates a variety of sensors that allows it to detect and smartly decide how to respond to the presence or absence of cups, lids, coffee, air pressure, temperature, position, etc.

The servo motor controlled filling device is designed to provide high accuracy, extremely smooth operation at all speeds.

This machine can produce both dolce gusto capsules with or without inside seal

SPECIFICATIONS

| Model | AF-H1 |

| Filling head | 1 head |

| Filling Accuracy | ±0.2g |

| Machine speed | 1500-1800 cph |

| Voltage | 220V/60HZ/3PH |

| Machine size | 1800*900*2000mm |

| Machine weight | 500KGS |

| Note | This is a custom-build machine, so each machine specifications will have different |

FEATURES

- Fast speed: 1 lane working, Up to 30 cycles/min, Produce up to 30 capsules/min

- Maintenance-free, backlash-free carrier plates driven by pneumatic cylinders to transport the containers

- Vertical Empty capsules storage and dropping system to save labors and time

- Self-sufficient filling module,Servomotor driven volumetric augers to keep high and stable filling accuracy

- Operator-friendly hoppers emptying and cleaning design, less than 5 mins fast clean

- Sealing temperature adjustable, beautiful and tight seal guaranteed.

- Incorporates a variety of sensors that allows it to detect and smartly decide how to respond to the presence or absence of cups, lids, coffee, air pressure, temperature, position, etc

- Standard control system from Omron or Siemens or Allen Bradley

- Various exit options for different second packaging solutions.

- High-efficiency Nitrogen flushing system, keep over 95% Nitrogen inside.

- Easy cleaning and product change, even between coffee and soluble powders

- The entire production process can be easily monitored by an operator performing all operations on the front side of the machine

- Safety Door: Open door, machine stop

FUNCTIONS

- Vertical capsules feeding system

- Automatic detect whether capsules well loaded on the machine by sensor.

- Servo motor to fill coffee while vibrating, weight around 7-12g ( can be adjust)(Nitrogen flushing here)

- Clean the capsule edge and press the coffee tightly

- Put pre-cut lids (can also use rolled film)

- Seal inside perforated film/Paper filter (Nitrogen flushing here)

- Seal outside aluminum/plastic film

- Output to the conveyor

OPTIONAL FUNCTIONS

☆ Inline weight detector

☆ Auto Screw tea feeder

☆ Cutting and putting the filter on the capsule button.

☆ Pack 1/10/20 pcs in one bag machine

☆ Pack 4/10 pcs in one box machine

SAMPLES MADE BY THIS MACHINE