AF-RK1 model is full automatic k cup filling sealing machine which can produce up to 25 CPM with filter inserting option.

Rotary type machine is very easy and convenient to operation, small foot print perfect for space limited production area. Heavy duty constructed, stainless steel surface, extremely reliable.

AF-RK1 machine able to fill and seal different type of pods like “K-cup®”, “Upshot®” ,“K-shot®”, with and without filter inserting option. Servo drive auger filler suitable for various of powder products: coffee, tea, hot chocolate etc.

This machine can produce different sizes of capsules, very easy to change the fitting parts.

AFPAK also offer empty K cups, K cup sealing lids, etc.

One stop K cup packaging solution, Only in AFPAK

SPECIFICATIONS

| Model | AF-RK1 K cup filling sealing machine |

| Filling head | 1 head |

| Filling Accuracy | ±0.3g |

| Machine speed | 1500-1800 cph |

| Voltage | 220V/60HZ/3PH |

| Machine size | 1200*1200*1800mm |

| Machine weight | 500KGS |

| Note | This is a custom-build machine, so each machine spec |

FEATURES

- Servo motor drive in line machine.

- Automatic vacuum transfer feeding system with permanent Nitrogen level.

- Stainless steel AISI 304 constructioninclude frame and electrical box.

- All electronics parts: PLC, Touch screen, Servo motor, Temperature—“OMRON” Japan.

- All pneumatic components: “SMC” Japan.

- All electrical parts and components: “Schneider” France.

- Servo motor Auger filler with PLC control.

- Robots station for ready cup positioning.

- Roll stock cut/seal or precut aluminum foil sealing.

- US and Canada safety standard.

FUNCTIONS

☆ Automatic drop empty K cup

☆ Automatic detect whether K cup well loaded on the machine by sensor.

☆ Insert the filter into K cup by Machine.

☆ Servo motor to fill coffee while vibrating, weight around 8-12g ( can be adjust) (Nitrogen flush here)

☆ Auto suck Foil Lids ( Or roll film, cutting and sealing) (Nitrogen flush here)

☆ Auto detect whether the foil lids is ready by Sensor (Nitrogen flush here)

☆ Auto Seal

☆ Output the finished K cups

SAMPLES MADE BY THIS MACHINE

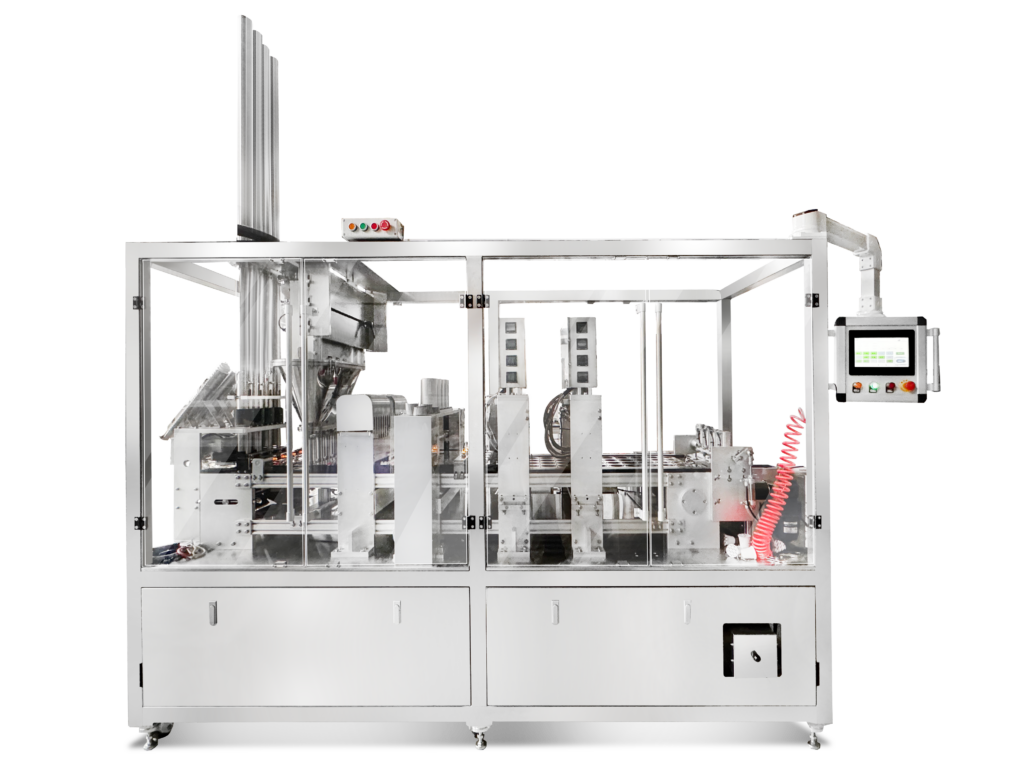

Machine Pictures