K Cup Packaging Machine – The Ultimate Guide

If you are a K Cup manufacturer and have been struggling to meet the demand, we have a solution for you. K Cup packaging machine is the right answer to your problem. However, it is not recommended to get the first K Cup packaging machine that you come across.

There are many models available for K Cup packaging machines from different brands. One of the most popular and known manufacturers of K Cup packaging machines is AFPAK with a wide variety of models for different customers.

No matter what level of production you do, you will find a suitable K Cup packaging machine at AFPAK. Whether you are a new entrant or a big player in the market, we have the right machines for you. But before you go out shopping for a K Cup packaging machine, let’s help you understand what it is, how to get it, maintain and make a profit.

What Is A K Cup Packaging Machine?

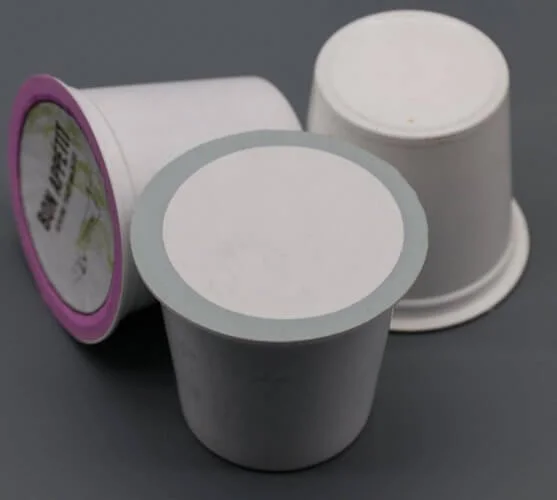

K Cup packaging machine is used for packing the coffee capsules. The capsules are made up of aluminum or plastic. They are filled with a fine powder of coffee, enough for a single cup. These capsules are then used to make coffee. If you are buying a K Cup packaging machine then you must keep in mind the following points:

- Variety of the capsule that you want to manufacture

- Stability and smoothness of machine operation

- Quality of appliance and the material used by the brand

- Has the right design for your production plant

Why Should You Get a K Cup Packaging Machine From Us?

AFPAK is one of the oldest and most reliable manufacturers and vendors of K Cup packaging machine. You will not find a more advanced catalog of K Cup packaging machines in the Chinese market. Our services are diverse and are designed by keeping the client in mind. Here is what you can expect from us:

Technical support

Technical support for your K Cup packaging machine is available throughout the year. You can call us on our number in case it is an emergency. In case of less urgent matters, you can write an email to our customer support team and they will get back to you asap.

Manuals

Manuals included with your K Cup packaging machine feature color photos and diagrams highlighting operating procedures, adjustment points, settings, change-over procedures, and maintenance areas. Also included with the manuals are user guides, wiring diagrams, electrical pneumatic, and mechanical spare parts lists. Troubleshooting guides and preventive maintenance schedules are also included.

Replacement Parts

Replacement parts for your K Cup packaging machine can be obtained through our Service and Support Department. You can call or email us to enquire about the availability. We can ship them to you anywhere in the world. If we are out of stock, we can always manufacture on demand.

Education and Training

During the installation of your K Cup packaging machine, we will train your operators to properly and efficiently run your new equipment. We will also work with your technical staff and demonstrate change-over procedures, troubleshooting methods and preventive maintenance areas. All of this can be done over video call.

Remote System Monitoring

In case you are having trouble with K Cup packaging machine operation, you can send us pictures of the issues. Our technicians can then guide your technicians about the issue and how to solve it.

Warranty

The Initial Warranty guarantees the proper functioning of the equipment purchased. The warranty period begins from the date of delivery, even if for any reason commissioning of the machine is delayed.

The Lifetime Warranty covers the machine’s frame against defects in material or craftsmanship for the life of the machine. Parts manufactured by AFPAK are covered for five years against defects in material or craftsmanship. Purchased parts are covered for two years against defects in material or craftsmanship. Wear parts such as suction cups, belts, etc. are not covered.

Integration Services

AFPAK can help you use our K Cup packaging machine to be integrated with new or existing systems. Integration of a new system includes equipment placement and alignment, transitions, communications and control systems, line start-up, and debugging. Integration to an older or existing system includes these same services plus retrofitting older equipment to be compatible with modern controls.

Do You Include All The Parts With K Cup Packaging Machine?

When you order a K Cup packaging machine, we make sure to send the complete package. This means you can start operating the machine once you have assembled and installed everything. All necessary parts needed for K Cup packaging machine operation are included in the package.

Some sellers choose to sell upgrades of the parts separately. However, at AFPAK, you get all the up-to-date parts. However, if you need spare parts, you would have to order them separately. They can be made on-demand as well. This is because our machines are made from premium parts that do not wear out easily.

You can always ask the seller before purchasing whether they provide spare parts with the Machine or not. Manufacturers who add spare parts usually add those which they know can wear out quickly. To compensate for this, they send in some extras so that you won’t have to pay to get them replaced anytime soon.

What Is The Design Of A K Cup Packaging Machine?

K Cup packaging machine comes either in a rotary or inline design. It takes up space based on the design you get. The rotary design of a K Cup packaging machine comes in a smaller package as compared to the inline design.

Since the rotary design K Cup packaging machine works in a circular motion, it can do everything in a compact body. However, the inline design takes up much more space as it works similar to how assembly lines work but at a much smaller scale.

You can choose to go for either design based on your need and availability of space. Both have their own advantages and disadvantages. It mainly depends on what works for you as both are great designs.

Can I Package Different Sizes Of K Cups?

Yes, you can. However, you cannot package different sizes of K Cups in a K Cup packaging machine at the same time. If you wish to change the size of your K Cups, you would have to change the settings. Once the settings have been changed, you cannot go back to packaging smaller sizes unless the settings are changed again.

Moreover, it is vital that you check out the specifications of the K Cup packaging machine. It will help you determine whether which sizes of K Cups it supports. You can also talk to the manufacturer and discuss your options with them.

It is also important to note that you cannot use the machine while you are changing the settings to fill bigger or smaller K Cups.

Are The Parts Of A K Cup Packaging Machine Durable?

If you are spending a good amount on a K Cup packaging machine, it is important that you enquire about the quality of the parts. Most reliable manufacturers only use premium parts to ensure high durability and the long life of the K Cup packaging machine. To find out if the machine is of good quality, you must look for the following:

Manufacturer

Manufacturers with good reviews are always reliable. People who have left good comments on their pages are customers who liked the quality of the products. You should trust other players of the industry among other factors for the reliability of machines from a K Cup packaging machine manufacturer.

Material

Reliable manufacturers make sure to mention the materials used to make the K Cup packaging machine in the specifications. If a manufacturer has not mentioned the materials, make sure to ask them.

Research on the best materials for the K Cup packaging machine to ensure you are getting a solid product. Usually, a K Cup packaging machine made from aluminum, stainless steel, and a little bit of plastic for certain components is considered good. However, there are varying qualities of stainless steel, aluminum, and plastic as well.

Check out the grade of the material and avoid getting a K Cup packaging machine that has too much plastic.

Selling Price

If a manufacturer is selling a K Cup packaging machine at a significantly lower rate than the competition it means: either the machine is obsolete, or it is low quality. In either case, you don’t want it. So, don’t try to save some extra money. You might end up buying a low-quality product that can become obsolete in the long run.

Does A K Cup Packaging Machine Need Maintenace?

Yes, it is absolutely mandatory to maintain a K Cup packaging machine. It has a motor that needs the power to work all the components for packaging. If you don’t maintain the machine, it can go through harsher wear and tear which can cause issues. Here are some maintenance tips you must keep in mind:

- Regular cleaning and washing

- Make sure to oil the components which go through wear and tear

- Get replacements for worn out parts on time instead of delaying

- Get any damages repaired before they lead to a bigger issue

- Follow all the operation guidelines sent by the manufacturer

It is vital to follow these maintenance guidelines, and all others sent in by the manufacturer. Even though a K Cup packaging machine is a premium product, it still needs to be looked after to offer optimal performance.

How Long Does A K Cup Packaging Machine Lasts?

If you get a premium K Cup packaging machine, it will last you a long time. However, the life of any machine depends on several factors. If you use it in harsh conditions and do not maintain it properly, the lifespan will be reduced.

If you follow all regular maintenance guidelines by the manufacturer it will last longer even than the time frame claimed by the manufacturer. Maintenance of a K Cup packaging machine is not difficult either. In most cases, it only requires regular cleaning and you will be good to go for a long time.

How Do I Know If The K Cup Packaging Machine I Ordered Is Good Quality?

The fact that you have purchased from a known manufacturer with good reviews and brand popularity means your K Cup packaging machine is of good quality. However, there are still some checking tips that you can follow to make sure:

- Doing a test run to check out the workings of the main motor

- Checking for any major or minor damages on the machine or the components

- Follow all manufacturer guidelines to install and operate and see if it produces results as mentioned

- Ensure all components are in the right place and in good working condition.

What Should I Look For In A Perfect K Cup Packaging Machine?

What’s perfect for someone else might not be perfect for you. The K Cup packaging machine that will suit you the best is the one that fulfills all your needs. At AFPAK, we guide our clients to the most suitable options so that they can make the most out of their investments.

We ask some questions which help users determine which machine will work best for them:

By what capacity do you want to increase production?

Capacity is a big indicator to find a suitable K Cup packaging machine. For instance, if you want to increase your capacity by 40-50 cups per minute, we will recommend our H1 K Cup packaging machine.

For a customer who wants to increase production by 300-400 cups per minute, we recommend our H2-6 K Cup Packaging machine. It has multiple lanes that package K Cup simultaneously.

What type of K Cup packaging machine do you want?

Based on your preferred choice we can recommend the right model. For instance, if you have a really big space, you can go for the inline models.

Similarly, if you do not have that big of a space, a rotary model will work best for your production plant.

What is your budget?

We make premium K Cup packaging machines that fall under different budget options. You might get fewer features if you are willing to spend less. However, even our low-cost models have the best quality.

What Happens If A K Cup packaging machine Breaks Down?

K Cup packaging machine is a premium product made from solid materials. The chances of the machine breaking down are quite low. However, if you have bought from a non-reliable manufacturer, it might break. Moreover, if any unfortunate incident occurs, such as an accident, the machine can break down as well. In such a scenario you must do the following:

- Cut the power of the machine so that it stops running

- Avoid using it again before getting any technician or professional assistance

- Hire a local technician

- Get in contact with the manufacturer

It is highly likely that the local technician and the manufacturer will be able to resolve the issue for you. In case the local technician fails to do anything some reliable manufacturers offer to ship the Machine back and repair it if they can’t. This option is recommended only in extreme situations where all other avenues of hope are down.

What Things Should I Keep In Mind Before Operating A K Cup Packaging Machine?

It really depends on the type, model, and make of a K Cup packaging machine. However, there are some general things that you can follow:

- We must check to ensure that all components are complete and reliable and whether the circuit system is safe and intact. Check the lubrication condition of each lubrication point and whether each part runs smoothly.

- Check whether the screws are tightened. If they are loose, we should pull them in time. We also need to check whether the upper and lower molds move flexibly and smoothly and cooperate reasonably.

- When the machine is running, your hands should not be close to any part of the machine in motion to prevent personal injury caused by inertia. And when installing or replacing parts, turn off the main power supply to avoid danger.

- The operator shall not leave when the machine is running and always check the operation of the equipment. If the device is abnormal, it will shut down immediately and should eliminate the fault. Strictly implement the operating procedures of the capsule filling machine, and deal with the problems in time.

Will I Get Warranty With K Cup Packaging Machine?

Yes, you will get a warranty with a K Cup packaging machine if you are purchasing from a reliable manufacturer. However, chances are you won’t have to claim the warranty as the K Cup packaging machine is a premium product that does not break down or malfunction. Unless you do not maintain it and use it in harsh conditions, it will last you a long time without any need to claim a warranty.

Also, make sure to understand the terms and conditions of the warranty. Manufacturers who offer a warranty have mentioned under what circumstances it stays valid. For instance, if you fail to follow the user manual and instructions by the manufacturer, you won’t be able to claim the warranty.

Is It Possible To Ship A K Cup Packaging Machine From China?

Yes, it is very much possible to ship a K Cup packaging machine from China. In fact, most K Cup producers import their K Cup packaging machines from Chinese companies. You will need the assistance of a shipping agent to get a K Cup packaging machine from China. You can find many agents online. However, in case you are new to this and need assistance, you can always ask your manufacturer.

Most manufacturers offer shipping as part of the deal. They handle everything related to shipping from their end. All you have to do is pick up the package from the old location. In most cases, it can reach directly to you.

To Conclude

K Cup packaging machine is an incredible innovation. It has sped up the packaging process and allows producers to meet the exponentially rising demand for K Cups. If you are in the industry then it is a great opportunity to use our modern K Cup packaging machine and become a big player in the industry.